by Ravindra Warang

7 minutes

Inside a 3D Cell Culture Lab: Equipment, Costs & Setup Guide

Learn how to build a 3D cell culture lab from scratch—tools, workflow changes, costs, and expert tips to future-proof your research.

It all began with a simple experiment in a shared university lab — a few cells suspended in a gel, imitating the behavior of a liver. That initial 3D culture experiment not only succeeded but also raised numerous questions that couldn't be addressed using conventional 2D cell culture techniques.

Today, laboratories worldwide are racing to create dedicated spaces for 3D cell culture, driven by the needs of personalized medicine, toxicology, drug development, and more. This shift towards advanced methods emphasizes the significance of establishing proper facilities for 3D cell culture.

But moving from 2D to 3D culture isn't just about purchasing new containers. It demands a change in mindset, a different approach to workflow design, and the right infrastructure. Whether you're starting from scratch or improving your existing lab, this guide outlines everything you need — from essential equipment to budget planning and efficient workflow design.

As you begin this process, think about crucial factors like:

- Choosing the right media for various cell types

- Determining optimal media and environmental conditions for mammalian and non-mammalian cells in 3D cultures

- Following cell culture safety protocols

- Conducting thorough cell line authentication to ensure cell viability throughout your experiments

Additionally, understanding drug metabolism in 3D cultures will be vital as you investigate gene expression changes in 3D cultures compared to traditional methods.

Why Build a 3D Cell Culture Lab Now?

There’s a clear shift happening across the life sciences sector. 3D cell cultures are no longer experimental—they're becoming essential for various applications, including predictive drug development and personalized medicine. Here’s why:

- Regulatory bodies are encouraging regulatory alternatives to animal testing.

- Personalized medicine models demand better patient-specific systems that accurately reflect gene expression in 3d cultures.

- Drug development needs models that better predict clinical outcomes, making them vital for effective translational research.

- New tools like organoids, organ-on-chip systems, and bioprinters are more accessible than ever.

Labs that integrate 3D systems now position themselves at the forefront of precision therapeutics. By finding protocols and equipment recommendations for setting up a 3D cell culture laboratory focused on spheroid formation and analysis, researchers can effectively study complex biological processes, including the behavior of cancer cells under various culture conditions for cells.

Additionally, careful consideration of laboratory design to maintain sterility in cell culture labs is crucial. This includes applying standard protocols like aseptic technique to ensure reliable results. As the demand for innovative research methods grows, establishing a 3D cell culture lab becomes an indispensable step in advancing scientific discovery.

Essential Equipment for a 3D Cell Culture Lab

Let’s look at the core equipment categories you’ll need to effectively conduct cell culture and what they’re used for:

1. Basic Infrastructure

Every lab—2D or 3D—starts with foundational tools that constitute the basic infrastructure. These include:

- CO₂ incubators to maintain temperature and gas conditions essential for cell viability in 3D culture systems.

- Class II biological safety cabinets (BSCs) for sterile handling and protection against contamination.

- Inverted phase-contrast microscopes for thorough observation of cells, allowing you to monitor human bladder carcinoma cells and other specimens.

- Common tools like centrifuges, water baths, pipettes, and storage freezers that are standard in any existing tissue culture lab.

These are standard and likely already part of any established cell culture facility.

2. 3D Culture-Specific Equipment

Now comes the layer that sets a 3D lab apart:

- Ultra-low attachment (ULA) plates or hanging drop plates for scaffold-free spheroid culture, crucial for studying complex cell interactions.

- ECM substitutes such as Matrigel™, collagen, alginate, or PEG-based hydrogels to support scaffold-based or organoid cultures.

- Bioreactors and spinner flasks to grow 3D cultures uniformly over time, ensuring consistent nutrient delivery and waste removal.

- Cryopreservation systems to store organoids or stem cell lines for long-term use, preserving their viability for future experiments.

- Optional but helpful: media dispensers and liquid handling systems for automation, streamlining the process of preparing cell culture media.

3. Advanced Technologies (Optional but Valuable)

For more complex systems:

- Microfluidic devices are essential for organ-on-chip models where flow simulation is required, allowing for precise control of environmental conditions.

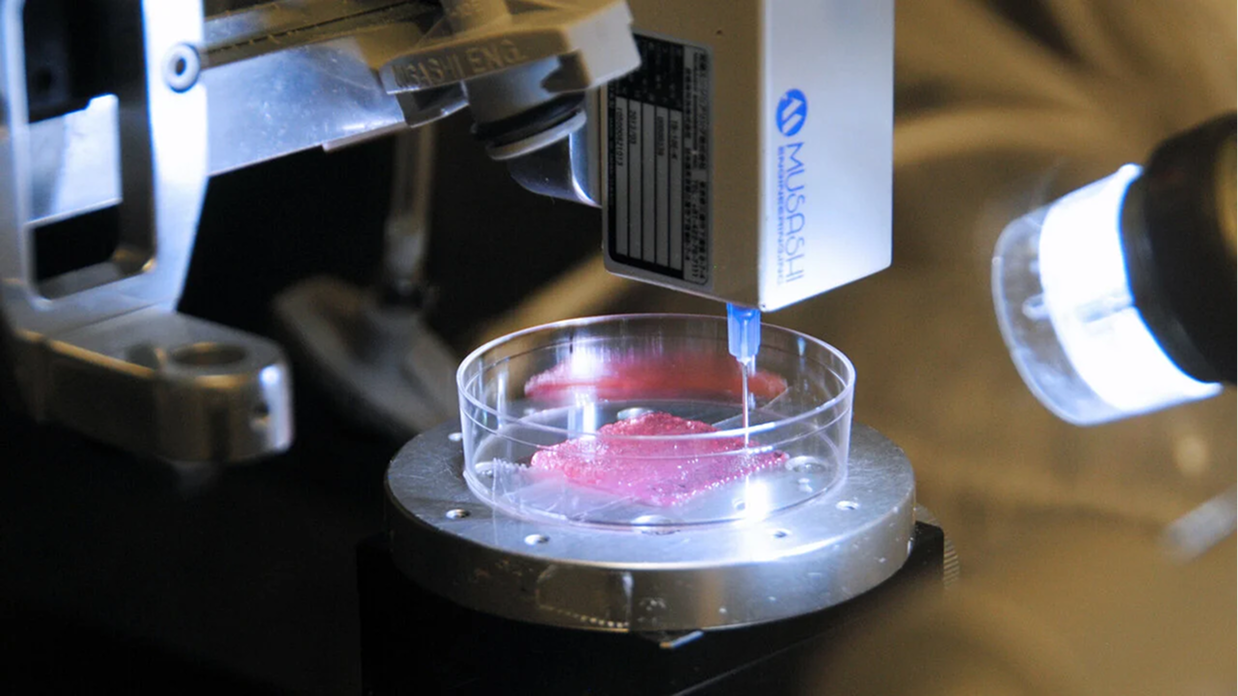

- 3D bioprinters like CELLINK Bio X or Aspect RX1 allow you to create structured, multicellular tissue constructs that mimic natural organs.

- Live-cell imaging platforms, including confocal or light sheet microscopes, are crucial for monitoring spatial behavior over time and assessing the effects of different variables on cell viability in 3D culture systems.

By understanding these essential equipment categories and their specific functions, you can effectively learn how to set up a 3D cell culture lab environment properly.

Cost Breakdown of Setting Up a 3D Lab

When considering a 3D cell culture lab setup, it's essential to understand that your lab equipment investment can vary significantly based on your ambition and specific applications such as gene expression studies or protein synthesis.

Here’s a detailed cost breakdown of 3D lab setup:

- Basic infrastructure (incubators, BSCs, microscopes) might cost between $20,000 and $40,000. This includes equipment necessary for maintaining sterile conditions and supporting spheroid formation techniques.

- 3D culture tools like ECMs, specialty plates, and reagents could add $5,000 to $15,000 annually in consumables. Be sure to consider the use of minimum essential medium (MEM) when selecting reagents.

- Bioreactors and spinner flasks costs typically range between $5,000 and $20,000. These are crucial for maintaining optimal growth conditions for vascular smooth muscle cells and other primary cells.

- High-end imaging systems such as confocal microscopes can run from $50,000 to over $150,000 depending on specs. Understanding confocal microscopes pricing is vital as these systems are essential for analyzing cellular structures in 3D cultures.

- Entry-level bioprinters start around $25,000, while advanced bioprinter expenses can exceed $100,000. These devices are integral to creating complex tissue architectures.

- Microfluidic systems costs vary between $10,000 and $50,000 depending on the modules. These systems allow precise control over experimental conditions and are ideal for studies involving dynamic cell interactions.

A small, functional lab might be set up with a $35,000–50,000 investment. However, for advanced workflows that require sophisticated techniques like cryopreservation or intricate cell line studies—such as choosing a cell line for experiments—plan for $150,000–300,000 or more.

Understanding the basic principles and techniques of cell culture work is crucial when navigating these costs and making informed decisions about your 3D lab setup.

How a 3D Cell Culture Lab Workflow Differs

Shifting from 2D to 3D cell culture isn’t just a hardware upgrade—it’s a fundamental process change that involves understanding key 3D cell culture workflow differences.

Key Differences in 3D Cell Culture Workflow

- Seeding: In 3D cultures, cells are embedded or suspended using techniques like matrix gels or the hanging drop technique for spheroids, instead of being plated on plastic.

- Feeding schedules: Nutrient diffusion in 3D cultures must be taken into account when planning feeding schedules. Media change schedules might need to be more frequent, as nutrient gradients play a larger role in keeping cells alive.

- Monitoring: Traditional 2D microscopes cannot easily capture the depth and spatial structure of complex structures like spheroids or organoids, so advanced imaging systems are required for monitoring 3D cultures.

- Data analysis: Analyzing data from 3D cell culture involves considering more factors such as spatial heterogeneity, cellular gradients, and functional outputs like beating cardiac cells or barrier formation in epithelial layers.

In essence, you’re building a micro-ecosystem that supports diverse cell types—like immortalized cells and osteoblasts—rather than just growing a monolayer. This shift also requires careful consideration of how to measure cell growth and confluency, as well as thorough contamination testing in cell cultures to ensure reliable results.

What Type of 3D Models Are You Building?

The type of 3D cell culture models you’re working with influences the kind of tools and workflows you'll need in your cell culture laboratory design:

- Tumor spheroids are best suited for ULA plates and low-shear bioreactors. They’re widely used in oncology drug screening applications and resistance modeling. Consider using the forced floating spheroid production method for consistent results.

- Organoids (gut, brain, liver, etc.) require ECM-rich gels like Matrigel™ and longer culture periods. These models are invaluable in disease modeling and therapy prediction, especially when working with HepG2 liver cells to assess drug metabolism.

- Scaffold-based cultures such as skin or cartilage use natural or synthetic scaffolds and often integrate bioreactors for mechanical stimulation. These cultures differ significantly from adherent cultures due to their complex architecture.

- Bioprinted tissues demand bioinks, nozzles, and CAD-style planning tools to build layered structures effectively. Ensure that you follow standard cell culture protocols to maintain viability.

- Organ-on-chip platforms require microfluidic interfaces, flow control pumps, and often co-culture capabilities. These systems offer advanced insights into physiological processes that traditional drug screening methods cannot.

Choosing your system defines your setup—not the other way around. Always remember to know biosafety requirements and safety practices in cell culture labs when working with these advanced 3D models.

Building the Right Team for 3D Cell Culture

Building a 3D cell culture team requires a diverse group of professionals with hybrid skills. Here are the essential roles you’ll need:

- Cell biologists to design and maintain the cultures, ensuring proper cell differentiation and studying cell morphology. Their expertise is crucial when working with specific cell lines like the MCF-7 cell line.

- Biomedical engineers in 3D labs to manage devices such as chips, pumps, and bioprinters. They will help integrate advanced technologies that facilitate complex lab setups.

- Imaging and data specialists to analyze 3D morphology, viability, and function. Their work is vital for understanding the benefits of 3D cell culture compared to 2D culture for lab setups.

- Lab technologists with expertise in standardizing SOPs and ensuring reproducibility. They will oversee processes like cryopreservation and thawing of cells, as well as maintaining sterile conditions in a laminar flow hood.

- Bioinformaticians for omics-based analysis, especially when integrating AI models or patient datasets. Their skills are essential in interpreting complex data arising from organoid culture workflows.

Investing in training and protocol harmonization is as important as equipment when establishing a successful 3D cell culture lab. Consider factors such as suspension cultures and the specific techniques required for different types of analyses.

Mistakes to Avoid in Your 3D Lab Setup

Here are common pitfalls that can sabotage your 3D workflow and lead to issues with reproducibility in 3D experiments:

- Don’t treat 3D cell culture like 2D. Revise your protocols for 3D vs 2D cultures, considering factors like diffusion, handling, and cell proliferation rates.

- Avoid under-investing in imaging for 3D cultures. Without techniques that provide optical sectioning or 3D views, you’re missing crucial insights that are essential for understanding cellular interactions.

- Don’t over-equip your lab. Start lean with your focus area—identify the advantages of 3D cell culture over 2D culture and build on success before expanding your equipment list.

- Ensure reproducibility by maintaining consistent quality in your extracellular matrix (ECM) preparations. Pay attention to cell passage number and plate types, as these can all affect outcomes. Document everything meticulously.

- Skip the guesswork when experimenting with different methods to create 3D cell cultures in the lab environment. Validate every step before scaling up or submitting data—consider using techniques like the hanging-drop method or forced-floating method.

- Be diligent about testing for mycoplasma infection in cell cultures, especially when working with immortalized cell lines.

By avoiding these common mistakes in 3D lab setup, you can create a more effective and reliable research environment.

Helpful Resources and Vendors to Explore

Here are a few credible organizations and companies offering resources for 3D cell culture tools, training, and support:

- ATCC: Offers 3D culture kits and educational materials, including matrices and scaffolds for various 3D cell culture methods.

- Corning Life Sciences: Supplies ECMs like Matrigel™ and spheroid-friendly plates, making them essential vendors for ECMs and plates.

- Emulate Inc.: Specializes in organ-on-chip systems, positioning themselves as leading organ-on-chip systems providers.

- MIMETAS: Offers high-throughput microfluidic platforms, ideal for exploring microfluidic technologies applied to 3D cell culture setups for drug screening applications.

- CELLINK (BICO): One of the most accessible bioprinting technology companies globally, known for their innovative bioprinting platforms.

- Hubrecht Organoid Technology (HUB): Recognized as organoid technology leaders in PDO creation and licensing.

- NIH & EU Consortia: Active in tissue chip programs and standardization frameworks that ensure adherence to biosafety levels.

These resources will help you navigate the complex landscape of 3D cell culture and related techniques such as subculturing/passaging cells techniques and agitation-based approaches.

Conclusion: The Future of 3D Cell Culture Labs Is Dimensional — Build for It

A 3D cell culture lab isn’t just a physical upgrade—it’s a crucial step toward more human-relevant predictive science. You’re no longer just growing cells; you’re engineering tissues through advanced tissue engineering techniques, mimicking disease processes with effective disease modeling, and shaping the next generation of therapeutic development.

Building this lab may take time, money, and upskilling—but the return is a closer match to clinical outcomes through improved clinical outcome prediction, better data for decision-making, and leadership in a fast-growing scientific space. Incorporating technologies like microfluidic 3D culture technology and rotating cell culture bioreactors such as spinner flasks will enhance your ability to study cell growth phases while maintaining strict aseptic techniques.

Whether you’re outfitting a small academic lab or expanding pharma R&D with a comprehensive bioprinting lab setup, now’s the time to move beyond flat biology. Embrace the future of 3D cell culture labs and start gaining insights into cellular behavior that traditional methods simply can’t provide. Consider the unique properties of suspension cells for culturing purposes to optimize your experiments and ensure accurate cell counting methods in culture.

FAQs (Frequently Asked Questions)

Q1: What do I need to start a 3D cell culture lab?

A basic setup for starting a 3D cell culture lab includes CO₂ incubators, biosafety cabinets (BSL-2), microscopes, ultra-low attachment plates, and ECM substrates like Matrigel™. Additionally, consider incorporating bioreactors or microfluidics to enhance cell-to-cell interactions in 3D cultures.

Q2: Is 3D cell culture expensive to set up?

The cost of 3D cell culture setup can be significant. A minimal setup might cost around $35,000, while advanced labs equipped with bioprinters and high-end imaging systems could exceed $150,000.

Q3: How is 3D cell culture different from 2D in terms of lab workflow?

Understanding the differences between 2D and 3D workflows is crucial. 3D culture involves distinct seeding, feeding, and imaging techniques due to factors like depth, gradients, and more complex biological behavior such as morphology changes.

Q4: Can I transition my 2D lab to 3D gradually?

Yes, transitioning from 2D to 3D lab environments is feasible. Many labs begin with simple spheroid systems using existing tools and basic equipment for cell culture lab activities, then expand to organoids, bioprinting, or organ-on-chip tools.

Q5: What skills are required to run a 3D lab effectively?

To effectively manage a 3D lab, you'll need expertise in cell biology, imaging, and SOP development. Additionally, familiarity with cell transfection procedures and the ability to select appropriate cell lines based on experiment needs and characteristics are essential. For advanced systems, engineering and data science skills are also valuable.

Q6: What are the essential applications of 3D cell culture labs?

3D cell culture labs are crucial for advancing personalized medicine, toxicology studies, and drug development. They enable human-relevant science by mimicking tissue architecture and disease states, facilitating therapeutic development and regulatory compliance.

Q7: What infrastructure and specialized equipment are needed to set up a 3D cell culture lab?

A 3D cell culture lab requires basic infrastructure such as CO₂ incubators, biosafety cabinets (BSCs), microscopes, centrifuges, water baths, pipettes, and storage freezers. Specialized tools include ultra-low attachment (ULA) plates or hanging drop plates for scaffold-free spheroid culture, extracellular matrix (ECM) substitutes like Matrigel™ and collagen, bioreactors or spinner flasks for uniform growth, cryopreservation systems for long-term storage, microfluidic devices for organ-on-chip models, advanced 3D bioprinters (e.g., CELLINK Bio X/Aspect RX1), and live-cell imaging platforms such as confocal or light sheet microscopes.

Q8: How does the workflow in 3D cell culture differ from traditional 2D culture methods?

3D cell culture workflows involve embedding or suspending cells within matrix gels or using hanging drop methods to promote three-dimensional growth. Nutrient diffusion limitations require adjusted feeding schedules and media changes to maintain gradients. Imaging techniques must accommodate depth and complex biological behavior not present in 2D cultures. Transitioning gradually from 2D to 3D is possible via spheroid systems progressing to organoids, bioprinting, and chip-based platforms.

Q9: What is the estimated cost range for establishing a 3D cell culture laboratory?

Basic infrastructure setup typically costs between $20,000 to $40,000. Annual expenses for 3D culture tools range from $5,000 to $15,000. Bioreactors or spinner flasks add another $5,000 to $20,000. High-end imaging systems can cost between $50,000 to over $150,000. Entry-level bioprinters start at around $25,000 while advanced bioprinters exceed $100,000. Microfluidic systems generally cost between $10,000 and $50,000. Overall minimal setups can be around $35k whereas advanced labs may exceed $150k.

Q10: Who should be included in a diverse team managing a 3D cell culture lab?

An effective 3D cell culture lab team comprises cell biologists who understand cellular behavior; biomedical engineers skilled in device fabrication; imaging and data specialists proficient in advanced microscopy; lab technologists experienced with protocols; and bioinformaticians capable of analyzing complex datasets. This multidisciplinary collaboration ensures robust experimental design and data interpretation.

Q11: What are common pitfalls when transitioning from 2D to 3D cell culture systems?

Common mistakes include treating 3D cultures like traditional 2D ones without accounting for differences in nutrient diffusion and cellular interactions; under-investing in appropriate imaging technologies required for complex structures; over-equipping the lab without validating workflows leading to inefficiencies; and lacking reproducibility or validation steps before scaling up or publishing data. Documenting every step meticulously helps avoid these issues.