ELMACH Highlights EPI-3015 PDA Blister Machine for High-Precision, Multi-Material Packaging

ELMACH introduces EPI-3015 PDA: compact, modular blister machine with 100% inspection and fast changeovers for regulated packaging.

Breaking News

Sep 02, 2025

Team Pharma Now

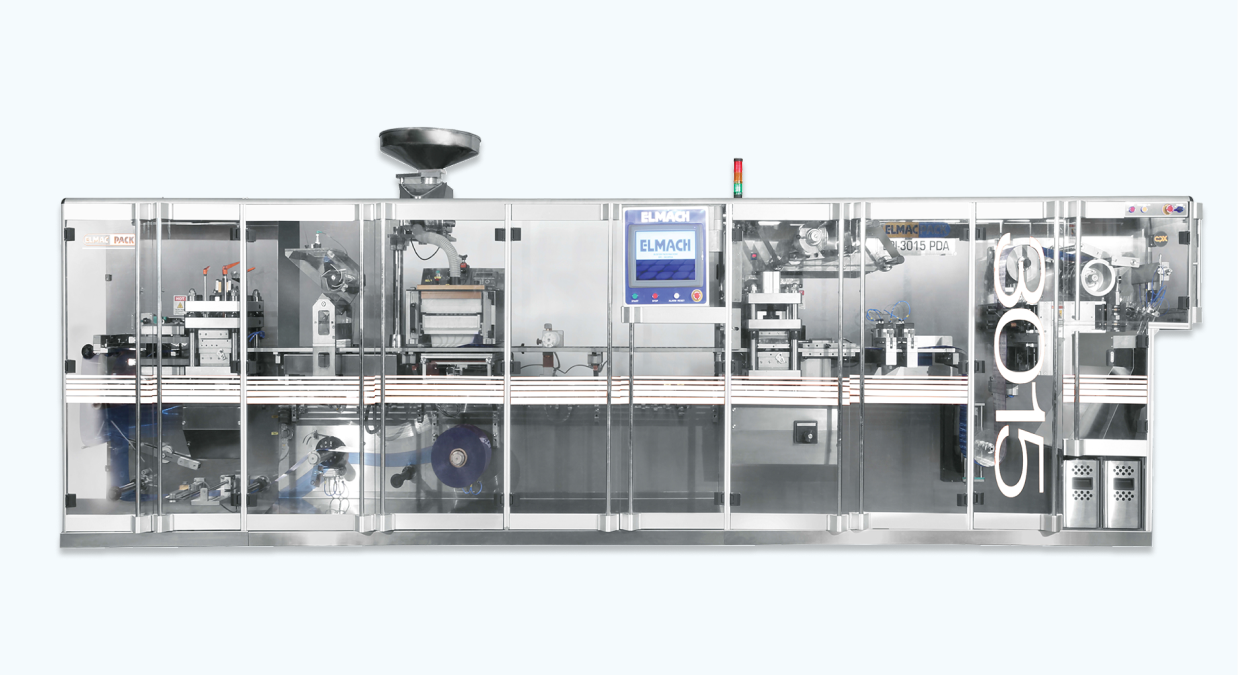

ELMACH, a global provider of solid-dose packaging technologies, highlights the EPI-3015 PDA, a flat forming, flat sealing machine engineered for both thermo-formed and cold-formed blister applications. Designed to elevate quality, flexibility, and integration across pharmaceutical, nutraceutical, consumer healthcare, and animal health markets, the EPI-3015 PDA combines servo-driven precision, intelligent inspection, and tool-less changeovers in a compact, GMP-compliant platform that meets the demanding standards of regulated production environments.

At the heart of the EPI-3015 PDA is equipped with a high-speed camera that enables 100% visual defect detection in real time. An integrated reject station with separate containers for scrap and misfilled blisters ensures only compliant product proceeds downstream, improving batch integrity and reducing the risk of contamination or rework. Its modular, servo-based design provides scalable, consistent operation across tablets, capsules, and softgels, while servo-driven actuation at all workstations ensures precise motion control and repeatable performance.

Operators benefit from a recipe-driven interface accessible through a user-friendly touchscreen HMI, which supports fast product changeovers and minimizes training time. Slide-in, tool-less changeover tooling allows for quick transitions between product types, supporting high SKU environments without extended downtime. The unit’s robust 4-column station design enhances structural durability and production stability, even during continuous and high-speed operation. A compact footprint makes the EPI-3015 PDA ideal for facilities where space is limited but performance cannot be compromised.

Engineered for high production versatility, the system supports both continuous and intermittent motion modes, while its forming capabilities span alu/alu and a wide range of materials, including PVC, PVC/PVDC, PVC/ACLAR, PET, and PETG. On-the-fly forming depth correction enables alignment adjustments without stopping the machine, while continuous monitoring of sealing pressure ensures blister integrity. A retractable sealing feature activates during production stops to prevent material damage and uphold package quality. With seamless upstream and downstream connectivity, the system can be integrated into new or existing cartoning lines with ease.

Designed to help manufacturers meet evolving regulatory expectations and traceability requirements, the EPI-3015 PDA offers a cost-effective solution for companies upgrading legacy blister inspection systems or investing in modular line expansion. Its combination of vision-based inspection, GMP-ready construction, servo-driven flexibility, and high-performance forming capabilities positions the EPI-3015 PDA as a next-generation platform for high-mix solid-dose packaging operations.