Romaco Innojet Unveils Heat Recovery System to Slash Fluid Bed Energy Use by 60%

Romaco Innojet's new heat recovery system cuts fluid bed energy use by 60% using a high-temperature industrial heat pump.

Breaking News

Jul 11, 2025

Simantini Singh Deo

Romaco Innojet is implementing a high-temperature heat pump in the fluid bed process for the very first time, enabling heat from the outlet air to be efficiently recovered. The thermal energy recovered in this way is fed directly into the process, cutting energy consumption by around 60 percent. Frictional heat from the outlet air fan is also used.

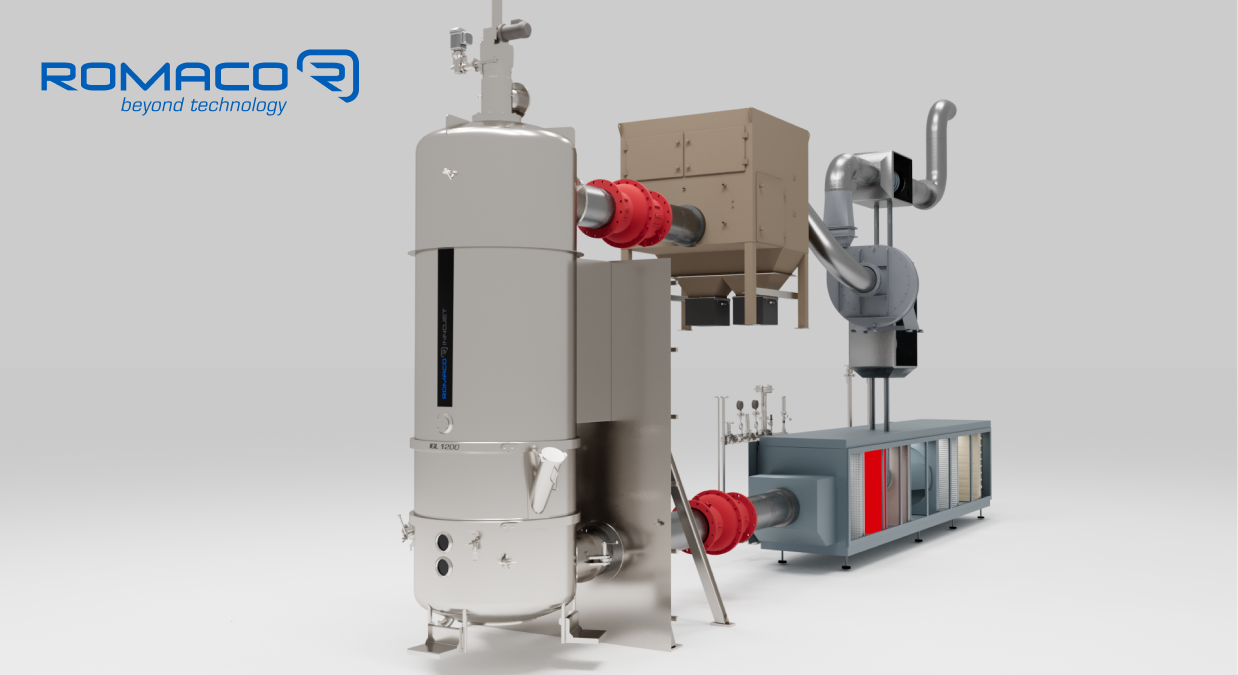

It is a well-known fact that the fluid bed process is extremely energy-intensive. Huge amounts of energy are needed for the drying process during the production and coating of granulates and pellets for the pharmaceutical, food and chemical industries. The Heat Recovery System (HRS) developed by Romaco Innojet for its VENTILUS® product family aims to sustainably reduce this enormous energy consumption. The innovative technology is very easy to implement in the fluid bed process and enables energy savings equivalent to up to 60 percent of the heat output.

The heart of the Romaco Innojet Heat Recovery System is an industrial heat pump rated for a flow temperature of up to 100°C. It responds flexibly to the outlet air conditions of the different processes running on the machine. The parameters dictated by the production process, such as air and spray flow rates or the required heating temperature, result in variable outlet air conditions and the heat pump adjusts its operation accordingly. The setpoints for the temperatures of the cold and hot water streams are set on the HMI panel or in the fluid bed processor’s automated process recipe system, which is also where users specify the process step in which the heat recovery system should be activated. The fluid bed process runs independently, whether or not heat recovery is active.

Efficient energy cycle

The water-to-water heat pump that is used for this purpose is no different from a standard commercial heat pump in terms of the way it works. The relatively low temperature level of the outlet air is sufficient to boil the refrigerant in the heat pump and transform it into a gaseous state. This gas is then compressed to high pressure, so that it heats up to a very high temperature and emits the heat to the processing machine’s inlet air via a water circuit. The energy transfer causes the refrigerant to cool down again, so that it condenses and flows through an expansion valve in a liquid state. It then expands due to the pressure drop and returns to its original temperature, whereupon the heat pump cycle begins anew.

In Romaco Innojet’s HRS Heat Recovery System, the heat pump is divided into two water circuits – one for the inlet air and one for the outlet air. The energy transfer is controlled using four heat exchangers. The thermal energy that is recovered from the outlet air is fed directly into the inlet air of the process and utilized solely to heat the process air stream. There is no longer any need for complex intermediate storage or secondary usage scenarios for the recovered energy.

Innovative use of outlet air heat

The frictional heat from the outlet air fan is also used by the recovery system in addition to the thermal energy from the process outlet air. The high-pressure fan, which pulls the process air through the fluid bed system, is situated in the outlet air handling unit upstream from the recovery module. It heats up the air by approximately 5 to 15°C. Thanks to the HRS, this energy can be fed directly into the heat pump and recovered rather than simply escaping into the atmosphere unused, together with the outlet air. Romaco Innojet has registered intellectual property rights regarding the development of the circular heat recovery system.

The heat pump achieves a COP of 3.5 on average – in other words, 3.5 times more energy is recovered than is used electrically. In relation to the fluid bed process, this means heating energy savings of up to 60 percent – equivalent to up to 50 tons fewer carbon dioxide emissions per year, depending on the size of the machine.

The Innojet fluid bed processors ship with an energy monitor that is integrated in the HMI to enable precise calculations of energy efficiency. This tool measures the exact consumption of both the system as a whole and its individual components. All energy streams, including recuperative heat recovery streams, are recorded over the machine’s entire service life. These values can be displayed in megawatt hours, carbon dioxide or carbon equivalents and are stored in the system. Robust data can be obtained in this way for sustainability reporting, which is mandatory for a growing number of companies worldwide.

Easy to implement

The HRS Heat Recovery System is very easy to implement in all new machines belonging to the Romaco Innojet VENTILUS® product family and IGL series. The system can also be retrofitted. At the InnoTech laboratory in Steinen, Germany, a V 150 featuring an integrated heat recovery system is available for product trials. A pharmaceutical manufacturer from southern Germany is the first to use the technology in practice – in a VENTILUS® processor with a maximum batch volume of 900 liters.

The Romaco Innojet HRS Heat Recovery system is particularly efficient when it comes to granulating and drying wet granules – in short, in all processes with high spray rates and high air consumption. The enormous energy saving potential where fluid bed processes are concerned represents an important step towards more sustainable production of pharmaceutical, food and chemical products. In 2024, Romaco was awarded its first-ever gold medal in the EcoVadis sustainability ratings for its commitment to climate protection.

More information will be available at POWTECH TECHNOPHARM from September 23 to 25, 2025, at NürnbergMesse, Exhibition Center 1, Nuremberg (Germany), Hall 9, Booth 9-549.

Romaco Group

Romaco is a leading international supplier of processing and packaging equipment specializing in engineering technologies for pharmaceutical products. The Group provides individual machines, lines and turnkey solutions for manufacturing, filling and packing powders, granulates, pellets, tablets, capsules, syringes, liquids and medical devices. The company also serves the food and chemical industries. Through its various technologies, Romaco is committed to sustainable production and to systematically reducing CO2 emissions.

The Romaco Group has its headquarters in Karlsruhe (Germany) and is part of Truking Technology, a globally operating high-tech enterprise based in Changsha (China). Truking’s core competency is handling and filling pharmaceutical liquids.

Romaco operates from six production sites worldwide, with a broad portfolio comprised of seven established product brands. Noack and Siebler (Karlsruhe, Germany) supply blister, heat-sealing and rigid tube filling machines. Macofar (Bologna, Italy) markets technologies for filling sterile and non-sterile powders and liquids. Promatic (also Bologna, Italy) specializes in cartoners, track & trace systems and case packers. Kilian (Cologne, Germany) is a leading manufacturer of tablet presses. Innojet (Steinen, Germany) is in the business of granulating and coating fine solid particles. Tecpharm (Barcelona, Spain) offers tablet coating technologies.

More than 930 highly skilled and committed Romaco employees are dedicated to the development of future product technologies and to the continuous implementation of internal improvement processes. The Romaco Group’s multi brand system solutions are sold worldwide through ten Sales & Service Centers and a dense network of local agent organizations. Over 12,000 installations delivered by Romaco are currently in use in more than 180 different countries.