by Ravindra Warang

7 minutes

Using 3D Cell Culture for Toxicity Testing: A Step-by-Step Framework

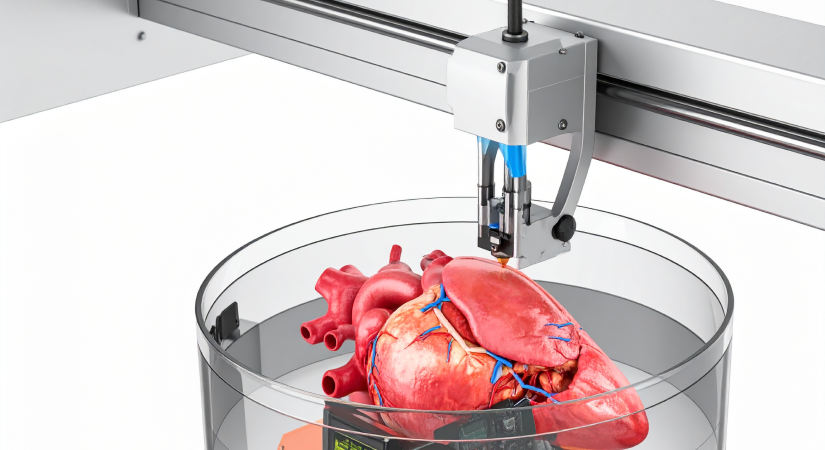

3D cell culture is transforming toxicity testing—offering more accurate, human-relevant models than outdated 2D systems. Learn how to use it.

In the early 2000s, a promising painkiller passed all standard toxicology tests — including 2D liver assays and animal studies. It entered clinical trials with confidence. But just weeks into Phase I, patients reported severe drug-induced liver injury (DILI) as a result of acetaminophen (APAP) exposure. Trials were halted. Millions lost. Years of work undone.

Why didn’t anyone see it coming?

Because biology isn’t flat. And neither is toxicity.

That failure — one of many in the industry — highlighted a fundamental flaw: 2D models don’t accurately replicate how real tissues respond to chemical exposure. Enter 3D cell culture toxicity testing. With their ability to mimic structure, gradients, and function, 3D systems offer a human-relevant toxicity assessment that is ethically sound and increasingly regulatory-friendly.

In this guide, we’ll break down exactly how to implement 3D cell culture for toxicity testing — step-by-step. We will explore advanced techniques such as hepatocyte spheroids and microfluidic chip designs that enhance the accuracy of toxicity evaluations while considering the inflammation response and other critical factors in tissue engineering applications. Discover how high-throughput screening is integrated with 3D cell culture platforms to streamline the assessment process effectively.

Step 1: Understand Why 3D Matters for Toxicity

Toxic responses in human tissues are often layered, meaning that drug penetration varies by depth and is dependent on oxygen/nutrient gradients. These responses are also tied to complex cell–cell interactions and extracellular matrix (ECM) interactions that are essential for normal tissue function.

Traditional 2D systems miss this complexity. In contrast, 3D models replicate multicellular arrangements that closely resemble real tissue, allowing for a more accurate representation of natural chemical diffusion processes. These models effectively mimic the dynamic expression of detoxifying enzymes and transporters expression that occur in vivo.

In toxicity testing, utilizing 3D cultures allows for more accurate prediction of drug-induced liver injury (DILI), cardiotoxicity, nephrotoxicity, and other adverse effects. This approach not only enhances the reliability of results but also provides insights into the physiological relevance of 3D cultures versus animal testing or 2D cultures.

As you explore advanced techniques like microfluidic circuit fabrication processes, consider investigating bubble removal strategies in microfluidic cell culture systems to ensure optimal conditions for studying toxic responses. Additionally, incorporating bioinks made from extracellular matrix components can further enrich cancer biology research using 3D cultures.

Step 2: Choose the Right 3D Model for Your Toxicity Endpoint

There’s no one-size-fits-all. Your model depends on the tissue type and endpoint being studied.

Here’s how to decide:

- Liver toxicity (DILI): Use liver spheroids or organoids composed of hepatocytes. These models exhibit CYP enzyme activity and albumin production, making them essential for assessing liver function and toxicity.

- Cardiotoxicity: Cardiac microtissues made up of beating cardiomyocytes are crucial for monitoring arrhythmia, QT prolongation, and cell death in response to compounds.

- Nephrotoxicity: Consider nephrotoxicity models such as kidney organoids or proximal tubule-on-chip systems that simulate filtration, reabsorption, and drug-induced injury effectively.

- Neurotoxicity: 3D brain spheroids or neural organoids are ideal for long-term studies of synaptic damage or degeneration in neurotoxic assessments.

- Pulmonary toxicity: Lung-on-chip models with alveolar cells and media perfusion can replicate inhalation exposure and barrier dysfunction while considering the thermal conductivity of silicon chips.

When selecting these models, assess how to maintain stable environmental conditions such as temperature and mechanical forces. Additionally, ensure that you follow standardized protocols for 3D culture preparation and maintenance to optimize your 3D toxicity screening efforts.

Step 3: Design the Exposure Protocol

Once your model is selected, plan how to introduce the test compound using appropriate exposure protocols for 3D models:

Direct Media Addition

Common for systemic drugs — add compound to the culture medium at desired concentration. This method ensures effective compound concentration maintenance.

Aerosol or Inhalation Exposure

For lung models, use air–liquid interface systems or microfluidic exposure chambers designed for aerosol exposure. This approach mimics natural human exposure routes more accurately.

Repeated Dosing

Chronic toxicity may require multi-day exposure to mimic drug accumulation effectively. Consider the effects of shear stress in dynamic cultures during repeated dosing.

Gradient Delivery

For solid tumor spheroids, create diffusion-based gradients to study how outer vs. core regions respond. This technique is essential in 3D cell culture toxicity testing to assess differential responses.

Key considerations:

- Match human exposure routes

- Maintain consistent compound concentration

- Validate compound stability in 3D systems: Ensure that conditions such as pH in chips during testing are controlled.

- Utilize 3D-bioprinting technology where applicable for standardized models.

- Incorporate analytical tools for 3D cell cultures data analysis to interpret results effectively.

By standardizing these techniques, you can ensure reliable outcomes in your toxicity assays, such as liver spheroid toxicity assays.

Step 4: Select Relevant 3D Readouts and Endpoints

3D systems support a broader range of endpoints than 2D cultures. When selecting readouts and endpoints, consider the organ type and toxicity class, especially in the context of drug safety testing applications using 3D hepatocyte cultures on chips.

Common endpoints include:

- Viability & Cytotoxicity: Assess ATP levels through viability assays, live/dead staining, and lactate dehydrogenase (LDH) release in cytotoxicity assays.

- Apoptosis/Necrosis: Utilize apoptosis detection methods such as caspase activity assays, TUNEL staining, and Annexin V assays.

- Functional markers for liver: Measure albumin and urea production, as well as CYP activity to assess liver toxicity.

- Cardiac: Determine beating rate and waveform characteristics to evaluate cardiac function.

- Kidney: Assess filtration efficiency through specific markers related to kidney toxicity.

- Lung and intestine toxicity: Evaluate barrier integrity using TEER (transepithelial resistance) and permeability assays.

- Inflammatory response profiling: Conduct cytokine release profiling (e.g., IL-6, TNF-α) to understand the inflammatory response.

- Imaging techniques in 3D toxicity testing: Apply Z-stack confocal microscopy for morphology assessment, necrosis zones identification, and tissue integrity evaluation.

Functional readouts often reveal early signs of toxicity before morphological changes appear—giving you a predictive advantage. Consider factors such as oxygen concentration and sterility in long-term cell culture when interpreting results. Additionally, be mindful of the cost and time challenges of 3D cultures compared to traditional methods.

By integrating computational models with these 3D readouts and endpoints, you can enhance the accuracy of organ-on-chip safety testing and better evaluate the effects of various compounds on complex biological systems.

Step 5: Validate the System for Reproducibility and Sensitivity

Before relying on a 3D model, especially in the context of the validation of 3D toxicity models, make sure it’s reproducible and sensitive enough to detect known toxicants. Assessing reproducibility in toxicity testing is crucial for ensuring reliable results.

- Use positive and negative controls: Include compounds with known toxicity and safety profiles to establish clear benchmarks.

- Run intra- and inter-assay comparisons: Are results consistent across replicates and timepoints? This step is essential for determining the sensitivity to known toxicants.

- Compare to historical 2D or in vivo data: How well does the 3D model reflect real-world outcomes? Consider conducting a thorough 2D vs 3D model comparison to highlight differences in efficacy.

- Document all handling SOPs: Even small changes in ECM concentration or seeding density can affect results. Ensure that standard operating procedures (SOPs) in 3D cultures are meticulously followed.

Remember, regulatory agencies want not just results — but robust, reproducible results that demonstrate clear correlations between cell viability and proliferation in 3D cultures and observed toxic effects.

Additionally, consider integrating glass microfluidics with PDMS membranes to enhance mass transfer while implementing effective contamination control strategies in microfluidics. This approach can be particularly beneficial when studying complex phenomena like drug-induced liver injury using a 3D model. Finally, utilize image analysis algorithms to accurately assess cellular responses within your validated systems.

Step 6: Analyze, Interpret, and Report Data in 3D Toxicity Testing

Data from 3D models can be complex — especially with spatial gradients in 3D models and mixed cell populations. Effectively conducting data analysis in 3D toxicity testing requires careful consideration of these factors.

Best practices for analysis:

- Use 3D-compatible imaging software (e.g., Imaris, CellProfiler 3D) to accurately capture and analyze data.

- Normalize results to viable cell number or protein content, ensuring that variations due to mixed cell populations are accounted for.

- Apply statistical models designed for spatial data to accurately interpret the effects observed in multicellular tumor spheroids.

- Consider integrating AI in high-content analysis for improved efficiency in toxicity classification and pattern recognition.

When reporting 3D toxicity data:

- Include full model description (cell types, ECM, duration) to provide context for your findings.

- Describe exposure method and endpoints clearly, highlighting any limitations of 2D cell culture that may affect interpretation.

- Present dose-response curves and IC₅₀/EC₅₀ values to illustrate the relationship between exposure and effect.

- Compare 3D vs 2D when possible — this strengthens your case by demonstrating the unique insights gained from 3D culture for DILI (drug-induced liver injury) studies.

Additionally, consider factors such as microbial contamination prevention and flow velocity simulation in microfluidic chambers to ensure the integrity of your experiments. Understand the benefits of using 3D cell culture in toxicity testing compared to traditional methods to support your conclusions effectively.

Step 7: Align with Regulatory Guidelines and Industry Standards

Global regulators are increasingly open to 3D-based toxicity data — especially when animal use is limited. This shift is reflected in key regulatory guidelines for 3D toxicity data that recognize the advantages of 3D cell culture over 2D culture in preclinical toxicity testing.

- The FDA Modernization Act 2.0 (2023) allows non-animal data (e.g., 3D models, chips) for preclinical safety assessment, emphasizing the role of complementary evidence to animal testing.

- OECD guidelines for organoid systems are expanding to include organoid and microphysiological systems that enhance the predictive accuracy of 3D data.

- EMA and PMDA support for 3D data in submissions, especially for liver, kidney, and cardiac toxicity, recognizing its importance in toxicology evaluation.

Agencies don’t demand that 3D data replaces animal testing — but they welcome it as complementary evidence, especially when the data improves predictive accuracy. For instance, using a 3D hepatocyte culture model can provide insights into oxygen diffusion and consumption in spheroids that traditional methods may overlook.

As you navigate these regulatory frameworks, consider how high-content screening 3D models can streamline your drug discovery processes while adhering to established guidelines.

Real-World Examples: How Pharma Is Using 3D Toxicity Models

1. AstraZeneca – Liver Spheroids for DILI

AstraZeneca uses liver spheroids to screen candidate compounds for CYP activity screening and hepatotoxicity detection. By using primary human hepatocyte spheroids, they effectively identify unsafe drugs before clinical trials, thus ensuring a safer drug development process.

2. Roche – Cardiac Microtissues

Roche employs cardiac microtissues to detect arrhythmia risk prediction in oncology drugs. These 3D models predict QT prolongation with higher accuracy than animal ECGs, offering a more reliable assessment of cardiac safety while mimicking in vivo conditions.

3. Takeda – Kidney Organoids

Takeda uses kidney organoids for nephrotoxicity screening in oncology and inflammation drug pipelines. These 3D readouts align better with clinical renal side effects than traditional animal testing studies, providing valuable insights into potential toxic effects.

4. Emulate Inc. – Organ-on-Chip Submissions

Emulate Inc. has submitted liver-on-chip models to the FDA as part of safety pharmacology data. This innovative approach helps reduce the number of required animal studies while assessing long-term cell culture viability and understanding mechanical forces on cells in culture chip environments.

Challenges and Considerations Before Scaling

Even with strong promise, implementing 3D toxicity testing comes with several challenges in 3D toxicity testing implementation:

- Cost: The cost of 3D assays is 2–3x higher than that of 2D assays initially, making budget considerations crucial for laboratories.

- Time: The time for culture establishment is longer, as these cultures take more time to establish and mature effectively.

- Data complexity: Data complexity in 3D models requires advanced imaging tools and new analytics techniques to accurately interpret results.

- SOP sensitivity: SOP sensitivity in 3D cultures is critical; slight changes in the extracellular matrix (ECM) or cell type can significantly affect outcomes.

- Training: Adequate training for 3D handling and imaging is essential, as teams need upskilling in these areas to effectively manage the complexities of 3d cell culture toxicity testing.

Still, many labs find that the cost of false negatives in 2D far outweighs these challenges—both financially and ethically. This is especially true when considering factors like drug interactions in vitro and the impact of substances such as diclofenac on liver toxicity.

As the field of biotechnology advances, understanding liver-on-a-chip models for drug toxicity testing becomes increasingly important, particularly for conditions like FGFR4 positive hepatocellular carcinoma. Additionally, high-throughput drug screening technologies are reshaping how we approach data analysis in toxicology studies.

Conclusion: A Safer, Smarter Way to Test Toxicity

Drug development is too expensive to rely on outdated models. The advantages of 3D cell culture in toxicity testing are clear: it’s not just an upgrade — it’s a shift toward biological relevance in drug development, enhanced patient safety in toxicity assessment, and regulatory evolution in toxicity testing.

Step by step, pharma is integrating these models as part of animal testing reduction strategies — not just to reduce animal testing, but to make smarter decisions earlier in the drug safety testing process. Whether you’re screening cancer drugs for acute drug toxicity or evaluating environmental chemicals, 3D systems offer a better window into how the human body will respond.

Innovations like the microfluidic perfusion incubator chip (PIC) are revolutionizing chronic toxicity testing by allowing more accurate drug cytotoxicity assessments while considering factors like oxidative stress.

The future of toxicity testing is structured, functional, and dimensional. And it’s already here.

FAQs

Q1: Why is 3D cell culture better for toxicity testing than 2D?

The advantages of 3D over 2D toxicity testing are significant, as 3D systems mimic real tissue structure and function. They capture gradients, cell–cell interactions, and enzyme activity, making them more predictive of in vivo toxicity. This is crucial for accurate assessments in environmental toxicology models.

Q2: What tissues can be modeled using 3D cell culture for toxicity studies?

Commonly modeled tissues in 3D toxicity studies include the liver, heart, kidney, lung, brain, and intestinal models. These are often created in the form of spheroids, organoids—such as human airway organoid (hAO)—or organ-on-chip platforms like Liver-on-a-chip.

Q3: Are 3D toxicity tests accepted by regulators?

Yes, the regulatory acceptance of 3D toxicity tests is growing. The FDA, EMA, and OECD are increasingly recognizing 3D models as valid supplements to animal testing—especially when data shows improved predictivity.

Q4: What are common challenges in 3D toxicity testing?

Key challenges in 3D toxicity testing include cost, time, data complexity, and protocol standardization. However, these challenges are outweighed by increased biological relevance and long-term ROI. It's essential to Explore methods to prevent contamination in long-term microfluidic cultures to ensure reliable results.

Q5: What advantages do 3D cell culture models offer in toxicity testing compared to traditional 2D cultures?

3D cell culture models better replicate complex tissue responses to chemical exposure by mimicking tissue structure, function, and cell-cell interactions. They capture gradients and enzyme activity more effectively, leading to improved accuracy and early detection of toxicity compared to 2D cultures.