by Ravindra Warang

7 minutes

Capsule Checkweighers: Precision Engineering for Oncology and Potent Drugs

Explore how capsule checkweighers ensure safe, precise dosing for oncology and high-potency drug manufacturing.

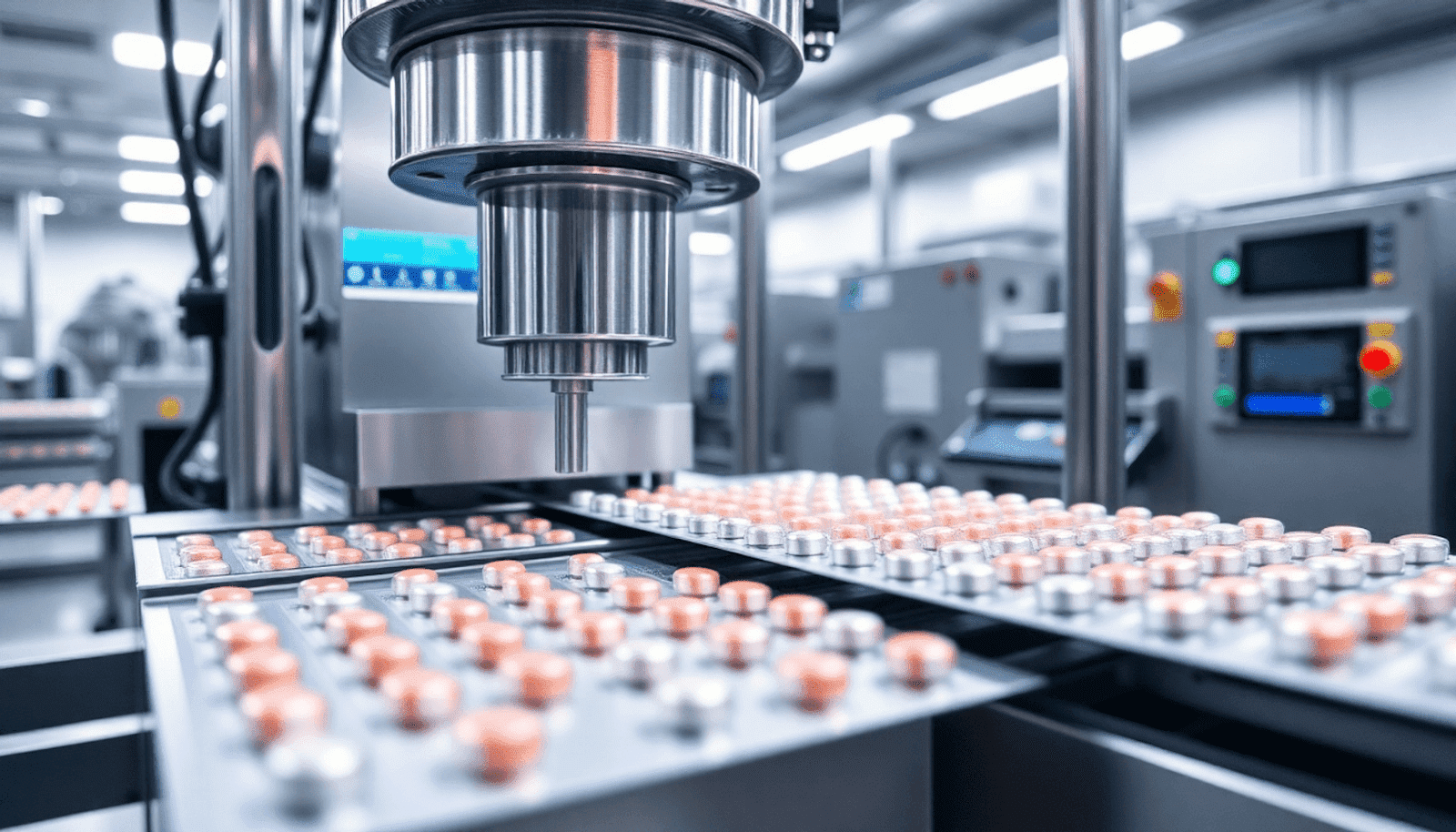

In a spotless pharma production suite in Hyderabad, a line of blister-packed oncology capsules speeds down a conveyor belt. At the end of this line sits a sleek capsule checkweigher—small in size but mighty in responsibility. As each capsule passes through it, the system verifies that every single unit contains exactly the required dosage—no more, no less. For patients fighting cancer or taking high potency active pharmaceutical ingredients (HPAPIs), that microgram-level accuracy could mean the difference between effective therapy and harmful overdose.

This is the realm where precision engineering becomes more than a manufacturing standard—it becomes a lifeline. In this article, we delve deep into how capsule checkweighers are transforming the production of oncology drugs and potent medications, where stakes are high, margins for error are minimal, and regulatory scrutiny is intense.

Why Capsule Checkweighing Is Crucial in Oncology and High-Potency Drug Manufacturing

High-potency active pharmaceutical ingredients (HPAPIs) and oncology drugs often require ultra-low dosage levels. Here’s why specialized checkweighers are indispensable:

- Toxicity Risk: Even a tiny deviation in dosage can lead to severe toxicity.

- Cost Factor: Oncology drugs and HPAPIs are expensive, so precision reduces waste.

- Compliance: Regulatory agencies enforce stringent dosage consistency standards.

- Patient Safety: Accurate dosing ensures therapeutic efficacy while avoiding side effects.

What Makes Capsule Checkweighers Unique?

While tablet checkweighers and traditional weighing systems suffice for general pharmaceuticals, capsule checkweighers are specifically engineered to address the complexities of powder or pellet-filled capsules. Key features include:

- Electromagnetic Force Restoration (EMFR) Technology: Enables ultra-high precision weighing.

- Microgram Sensitivity: Essential for oncology drugs with micro-dose requirements.

- High Throughput: Speeds of up to 200,000 capsules/hour without sacrificing accuracy.

- Integrated Sorting: Automatic ejection of under- or overfilled capsules.

Design Considerations for Handling Potent Drugs Safely

Working with oncology and potent APIs means that safety and containment are paramount. Checkweighers must be designed with features such as:

- Isolator-Ready Configurations: To maintain containment.

- Wash-In-Place (WIP) Systems: For easy cleaning and reduced exposure.

- HEPA Filtration: To trap fine powders during processing.

- Data Integrity Modules: To ensure audit trails for regulatory compliance (FDA 21 CFR Part 11).

Real-World Application: A Case Study in Oncology Drug Production

A major Indian CDMO specializing in oncology drugs integrated capsule checkweighers in its final packaging line. Within the first quarter:

- Batch rejections dropped by 23%

- Product yield increased by 11%

- Regulatory audit scores improved significantly

This highlights how incorporating the right checkweighing systems can directly impact bottom-line metrics and compliance success.

Table: Comparison of Key Capsule Checkweigher Features for Potent Drug Applications

Feature

Standard Checkweighers

Oncology-Grade Capsule Checkweighers

Weighing Sensitivity

Milligram level

Microgram level

Containment System

Basic dust control

Full isolator-compatible

Cleaning Mechanism

Manual

Wash-In-Place (WIP)

Sorting & Rejection

Manual or semi-auto

Fully automatic

Compliance

GMP

GMP + FDA 21 CFR Part 11

Conclusion: Engineering Confidence in Every Capsule

In oncology and potent drug manufacturing, each capsule is more than a unit—it’s a dose of hope, a critical part of someone’s treatment journey. By investing in specialized capsule checkweighers, pharma manufacturers are not just ticking regulatory boxes. They’re safeguarding lives, improving operational yields, and future-proofing their lines for more complex formulations.

As precision, automation, and compliance become inseparable in pharma manufacturing, capsule checkweighers are no longer an optional upgrade—they’re an essential assurance system.

FAQs (Frequently Asked Questions)

Q1. What are capsule checkweighers and why are they important in oncology drug manufacturing?

Capsule checkweighers are precision instruments used to verify dosage accuracy for oncology drugs and highly potent active pharmaceutical ingredients (HPAPIs). They play a critical role in reducing toxicity risk, minimizing waste, ensuring regulatory compliance, and enhancing patient safety.

Q2. What technologies do high-precision capsule checkweighers use?

Capsule checkweighers utilize advanced EMFR (Electromagnetic Force Restoration) technology that offers microgram sensitivity for ultra-high precision weighing. This enables high throughput operations of up to 200,000 capsules per hour along with integrated sorting capabilities to maintain quality control.

Q3. How do capsule checkweighers handle contamination risk?

Design features such as isolator-ready configurations, Wash-In-Place (WIP) systems, HEPA filtration, and data integrity modules enhance containment and cleanliness. These considerations help maintain sterile environments, prevent cross-contamination, support regulatory compliance, and ensure reliable data management during the weighing process.

Q4. How do key features vary among different capsule checkweigher models?

Key feature comparisons include weighing sensitivity (milligram vs. microgram), containment systems (basic dust control vs. full isolator compatibility), cleaning mechanisms (manual vs. Wash-In-Place), sorting and rejection methods (manual or semi-automatic vs. fully automatic), and compliance standards (GMP alone versus GMP plus 21 CFR Part 11).