by Ravindra Warang

7 minutes

HEPA vs ULPA Filters: Which One Does Your Cleanroom Need?

HEPA vs ULPA? Learn which filter your pharmaceutical cleanroom really needs in this expert guide.

In 2018, a U.S.-based pharmaceutical company faced unexpected microbial contamination during an aseptic filling process. Investigations revealed the cause: an old ULPA filter in the Grade A area that hadn't been tested for over a year. The consequences? Production stopped, drug release delayed, and increased regulatory scrutiny.

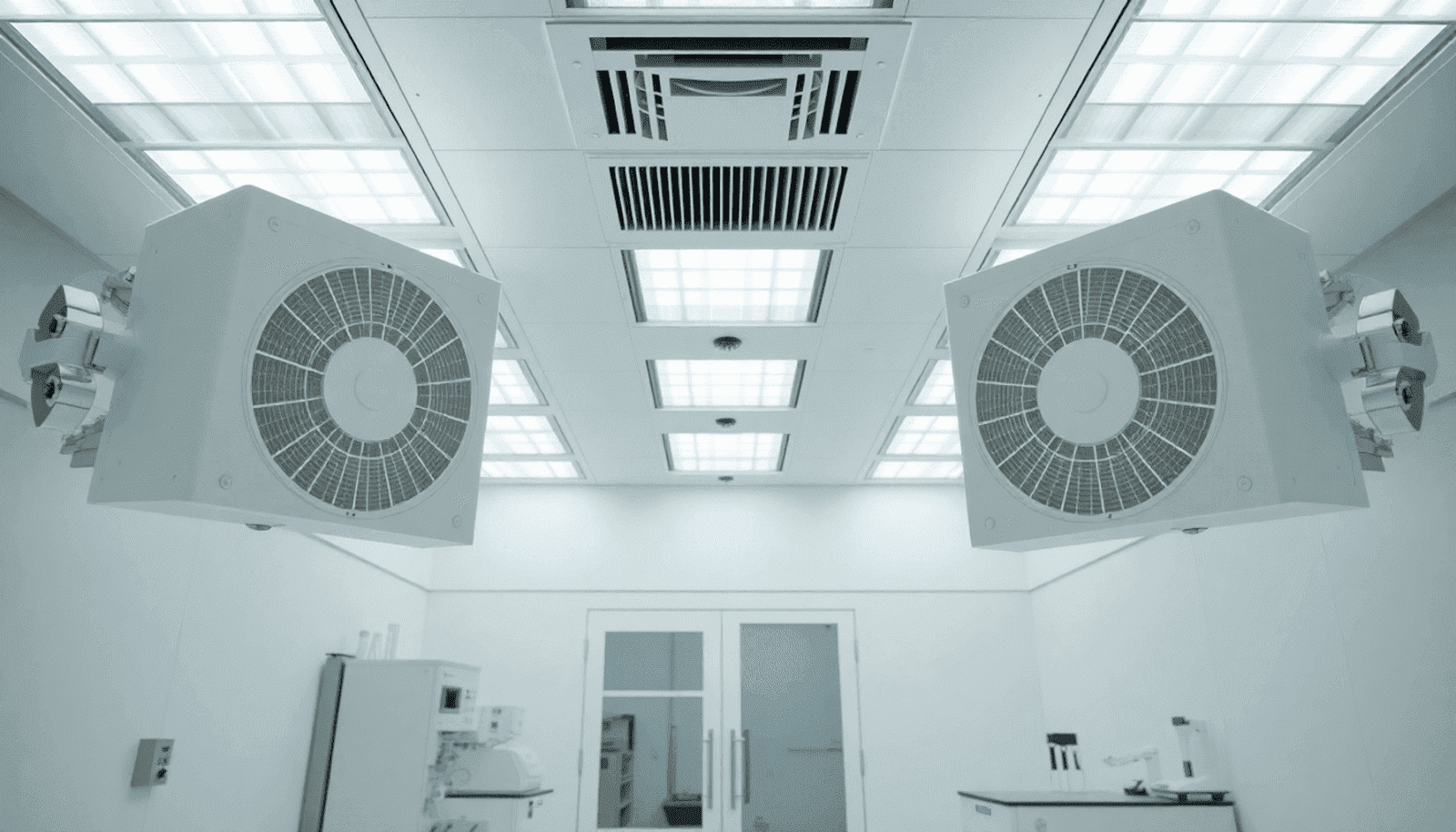

This incident highlights a critical yet often overlooked aspect of cleanroom design: air filtration systems. In pharmaceutical manufacturing, HEPA and ULPA filters serve as silent guardians, shielding sterile areas from particle contaminants and microbial intrusions. But how do you determine which one your cleanroom requires?

Understanding the differences between HEPA and ULPA filters is crucial for effective contamination control.

In this article, we'll explain the science, standards, and applications of HEPA and ULPA filters in simple terms. This knowledge will empower you to make informed decisions that consider safety compliance, cost analysis, and regulatory requirements.

Furthermore, when designing your cleanroom environment, it's important to be aware of the limitations of particulate air filters concerning gases and odors.

Understanding HEPA and ULPA Filters

HEPA Filters (High-Efficiency Particulate Air)

HEPA filters, known for their high air filter efficiency, remove at least 99.97% of airborne particles measuring ≥ 0.3 microns. This size is known as the Most Penetrating Particle Size (MPPS), where the filtration process is typically least efficient. Medical-grade HEPA filters are often constructed using advanced materials like borosilicate glass microfibers to ensure optimal particle size removal.

Key Attributes:

- Minimum Efficiency: 99.97%

- Particle Size: ≥ 0.3 µm

- Air Resistance: Moderate

- Lifespan: 3 to 5 years (with proper maintenance)

ULPA Filters (Ultra-Low Penetration Air)

ULPA filters are rated to remove at least 99.999% of particles ≥ 0.12 microns. While offering higher efficiency in the filtration process, they typically introduce greater airflow restriction and energy consumption due to their complex filter construction.

Key Attributes:

- Minimum Efficiency: 99.999%

- Particle Size: ≥ 0.12 µm

- Air Resistance: High

- Lifespan: 2 to 4 years

Differences Between HEPA and ULPA Filters

While both HEPA and ULPA filters are designed to capture small particles effectively, the key differences lie in their efficiency ratings, particle size removal capabilities, and air resistance levels. HEPA filters are generally preferred in environments like hospitals—discover why HEPA filters are preferred in hospitals over ULPA filters—due to their balanced performance and lower filter airflow restriction.

Similarities of HEPA and ULPA Filters

Both types of filters share common characteristics such as:

- High efficiency in removing airborne particles

- Utilization in cleanroom environments

- Importance in maintaining indoor air quality

Understanding these similarities can help you make informed decisions when selecting air filtration systems for specific applications like those offered by HEPAFORCE® Negative Air Machines.

Mechanism of Filtration

Both HEPA and ULPA filters use key filtration mechanisms to effectively remove particles from the air:

- Interception: Captures particles that pass close to a filter fiber

- Inertial impaction: Large particles collide with fibers due to inertia

- Diffusion: Smaller particles move randomly and collide with fibers, often influenced by Brownian motion

ULPA filters, with their finer fibers and denser filter media, are more efficient at capturing smaller particles but also introduce greater airflow restriction compared to HEPA filters. This increased efficiency is essential in environments like those maintained by Esco Lifesciences, especially in PCR cabinets that adhere to ASME standards.

When considering air filtration systems, it's important to conduct a filter cost comparison and find guidelines for infection control using air filtration systems.

HEPA vs ULPA Filter Comparison

This HEPA vs ULPA filter comparison table highlights key differences between these cleanroom air filters, including their efficiency, air resistance, maintenance costs, energy consumption, and typical lifespan. When selecting filters for environments that adhere to DOE standards, it's essential to consider the specific ISO classes required for your application.

Which Filter for Which Cleanroom?

ISO 5 / Grade A Zones

Used in aseptic filling and open product exposure zones within strict cleanroom classifications. These areas require extremely low particulate levels to ensure sterility. Recommended: ULPA filters or HEPA filters with unidirectional airflow, maintaining a high renewal rate (air changes per hour (ACH)).

ISO 6–7 / Grade B-C Zones

Background zones for aseptic processes or sterile preparation. In these cleanroom classifications, it's crucial to validate airflow patterns effectively. Recommended: HEPA filters, with a strong emphasis on HEPA testing to ensure proper filtration efficiency.

ISO 8 / Grade D Zones

Support areas such as component washing, staging, or equipment prep in various industries like microelectronics manufacturing. Recommended: HEPA filters with less dense configurations, considering the filtration mechanisms of interception, inertial impaction, and diffusion.

Installation & Testing Requirements

1. Integrity Testing

Both HEPA and ULPA filters require periodic leak testing as part of their installation requirements. This includes DOP/PAO challenge tests to ensure effectiveness. Any leak >0.01% disqualifies the filter, compromising its ability to maintain airborne dust and pathogen control.

2. Airflow Visualization

Smoke studies are essential for verifying unidirectional flow and the absence of turbulence—especially in Grade A operations within medical laboratories.

3. Filter Housing

Ensure proper seal and gel gasket compatibility in the filter housing. Improper installation can compromise even the best filters, undermining their integrity and overall performance.

4. Certification

Each filter must include:

- Serial number

- Efficiency certificate

- Leak test report

This certification is crucial for ensuring that the filters meet established testing requirements and standards.

Real-World Considerations

Energy and HVAC Load

ULPA filters can increase energy and HVAC load costs by 15–30%. When evaluating options, consider lifecycle cost analysis rather than just initial specifications.

Maintenance Cycles

Due to their higher media density, ULPA filters clog faster, leading to shorter maintenance cycles. This increase in maintenance frequency can significantly raise OPEX, especially in environments like cleanrooms that require strict air quality standards.

Risk vs. Benefit

For Grade A isolators or high-risk biologics, conducting a thorough risk vs. benefit analysis is crucial; ULPA filters offer stronger assurance. However, for most solid dosage forms or oral liquids, HEPA vs ULPA filters—HEPA is more than sufficient due to its effectiveness in various applications of HEPA filters.

Retrofitting Challenges

When considering retrofitting challenges, switching from HEPA to ULPA in an existing system requires careful HVAC revalidation and often necessitates blower upgrades. This is especially important in maintaining a negative air environment with HEPA filters while ensuring compliance with standards like IEST-RP-CC001.3 USA.

Common Mistakes to Avoid in Cleanrooms

1. Over-Specification of Filters

Installing ULPA filters in non-critical zones increases cost and energy use without added benefit. It's essential to assess the specific requirements of each area before deciding on high-efficiency air filters.

2. Infrequent Testing of Filters

Skipping annual PAO tests can result in undetected leaks and contamination. Regular testing is crucial to maintain air quality and ensure that filters are functioning effectively.

3. Incompatible Housings for Filters

Filters not seated properly can leak air and compromise cleanliness. Always ensure that the housing is compatible with the type of filter being used, especially when working in sensitive environments like electro-surgical operations.

4. One-Size-Fits-All Strategy

Each cleanroom should be evaluated for its specific process risk profile. Different industries have varying standards; for instance, when deciding between HEPA vs ULPA filters, it's vital to compare their efficiency and particle size capabilities based on the application.

Additionally, consider using pre-filters for ULPA filters to extend their lifespan and improve overall performance. Finally, take the time to learn about construction and materials of high efficiency air filters to make informed decisions that align with your cleanroom's needs.

Case Study: Biologics Plant Prevents Expensive Downtime

A biologics manufacturer in Singapore conducted a thorough investigation after noticing declining airflow rates in their Grade B corridor. This case study highlights the importance of maintaining compliance in cleanrooms.

The Investigation

The investigation revealed that prematurely clogged ULPA filters were the main issue.

The Solution

By replacing them with HEPA filters—known for their superior filtration mechanisms—and adjusting airflow velocity, they achieved an impressive HVAC load reduction of 22% without compromising regulatory standards.

The Results

This strategic move not only ensured a cleaner environment but also demonstrated significant cost savings with HEPA filters. Industries using HEPA and ULPA filters must regularly evaluate the cost effectiveness and lifespan of these filtration systems to ensure optimal performance.

Additionally, it's crucial to understand the differences in performance and application suitability between HEPA and ULPA filters, especially when considering equipment types that utilize such advanced filtration systems.

By carefully assessing filter efficiency and applications, manufacturers can better protect against contaminants like viruses while maintaining efficient operations.

Future of Filtration in Cleanrooms

The future of filtration in cleanrooms is being shaped by next-gen filters that go beyond just trapping particles. Innovations such as self-monitoring filters with embedded pressure sensors are changing how we maintain air quality. These advanced systems can provide real-time data on filter performance, ensuring optimal efficiency.

AI and HVAC Systems

AI-driven HVAC systems are becoming crucial in modern cleanroom environments. By adjusting airflow based on particle trends, these intelligent systems enhance control and compliance, making them essential in industries like pharmaceuticals.

Eco-Friendly Solutions

Eco-friendly filters with recyclable media are also gaining popularity, addressing sustainability concerns while maintaining high filtration standards. As cleanroom operators weigh the benefits of HEPA vs ULPA filters, it's important to understand how HEPA and ULPA filters work to make informed choices.

Pre-Filtration Benefits

Additionally, understanding the pre-filtration advantages air filters can provide is key for effective contamination control. For specific uses of ULPA filters, industries must evaluate their individual needs and consider factors such as cost savings with ULPA filters.

Cost and Control Reimagined

As these innovations reshape cost and control in pharmaceutical cleanrooms, integrating frameworks like the ICRA Matrix can further simplify processes and ensure adherence to best practices.

Conclusion:

Choosing between HEPA and ULPA filters isn't about deciding which one is superior—it's about finding the right fit for your specific requirements. Your decision should take into account various factors such as process risk assessment, product risk assessment, regulatory expectations, and operational cost analysis.

In pharmaceutical manufacturing quality control, air quality is of utmost importance. Whether you're upgrading to ULPA for sterile injectables or optimizing costs with HEPA for a Grade C corridor, make your choice carefully. Take into consideration factors like air filter limitations (gases, fumes, odors), filter life comparison between HEPA and ULPA. Using the wrong filter can put both quality and operator safety at risk when it comes to air filtration. On the other hand, selecting the right filter will provide you with an invisible barrier of protection.

It's crucial to understand when to utilize HEPA versus ULPA filters in healthcare environments, particularly since HEPA filters have a filtration efficiency of 99.97%, which is vital for upholding stringent cleanliness standards.

FAQs

Q1. What are the main differences between HEPA and ULPA filters in pharmaceutical manufacturing?

HEPA filters have 99.97% efficiency for particles ≥ 0.3 µm, moderate air resistance, and a lifespan of 3-5 years. ULPA filters provide higher efficiency at 99.999% for particles ≥ 0.12 µm, but have higher air resistance and a shorter lifespan of 2-4 years. ULPA filters use finer fibers and denser media, making them suitable for critical sterile zones requiring stronger microbial protection.

Q2. Why did microbial contamination occur in the U.S. pharma company related to ULPA filters?

The contamination was caused by an untested ULPA filter that failed to maintain sterile conditions, leading to halted production, delayed drug release, and regulatory scrutiny. Proper integrity testing, including leak tests and certification, is essential to ensure filter effectiveness and prevent microbial intrusions.

Q3. Which filter types are recommended for different ISO cleanroom grades in pharmaceutical production?

For ISO 5/Grade A zones involving aseptic filling or open product exposure, ULPA or HEPA filters with unidirectional airflow and high air renewal rates are recommended. ISO 6-7/Grade B-C zones should use HEPA filters with validated airflow patterns. ISO 8/Grade D support areas typically utilize less dense HEPA configurations.

Q4. What are common mistakes to avoid when selecting and maintaining air filters in pharma cleanrooms?

Common errors include over-specifying ULPA filters in non-critical zones leading to unnecessary costs and energy consumption, infrequent integrity testing risking contamination, using incompatible filter housings causing leaks, and applying a one-size-fits-all strategy without considering process risk or operational needs.

Q5. How do ULPA filters impact HVAC energy consumption compared to HEPA filters?

ULPA filters increase HVAC energy costs by approximately 15-30% due to their higher media density and air resistance which also causes faster clogging. This necessitates more frequent maintenance and potential blower upgrades when switching from HEPA to ULPA systems.

Q6. What future innovations are expected in pharmaceutical air filtration systems?

Upcoming advancements include self-monitoring filters equipped with pressure sensors for real-time performance tracking, AI-driven HVAC systems that adjust airflow based on particle trends to optimize cleanroom conditions, and eco-friendly filters made from recyclable media aiming to reduce environmental impact while maintaining stringent air quality standards.