by Ravindra Warang

7 minutes

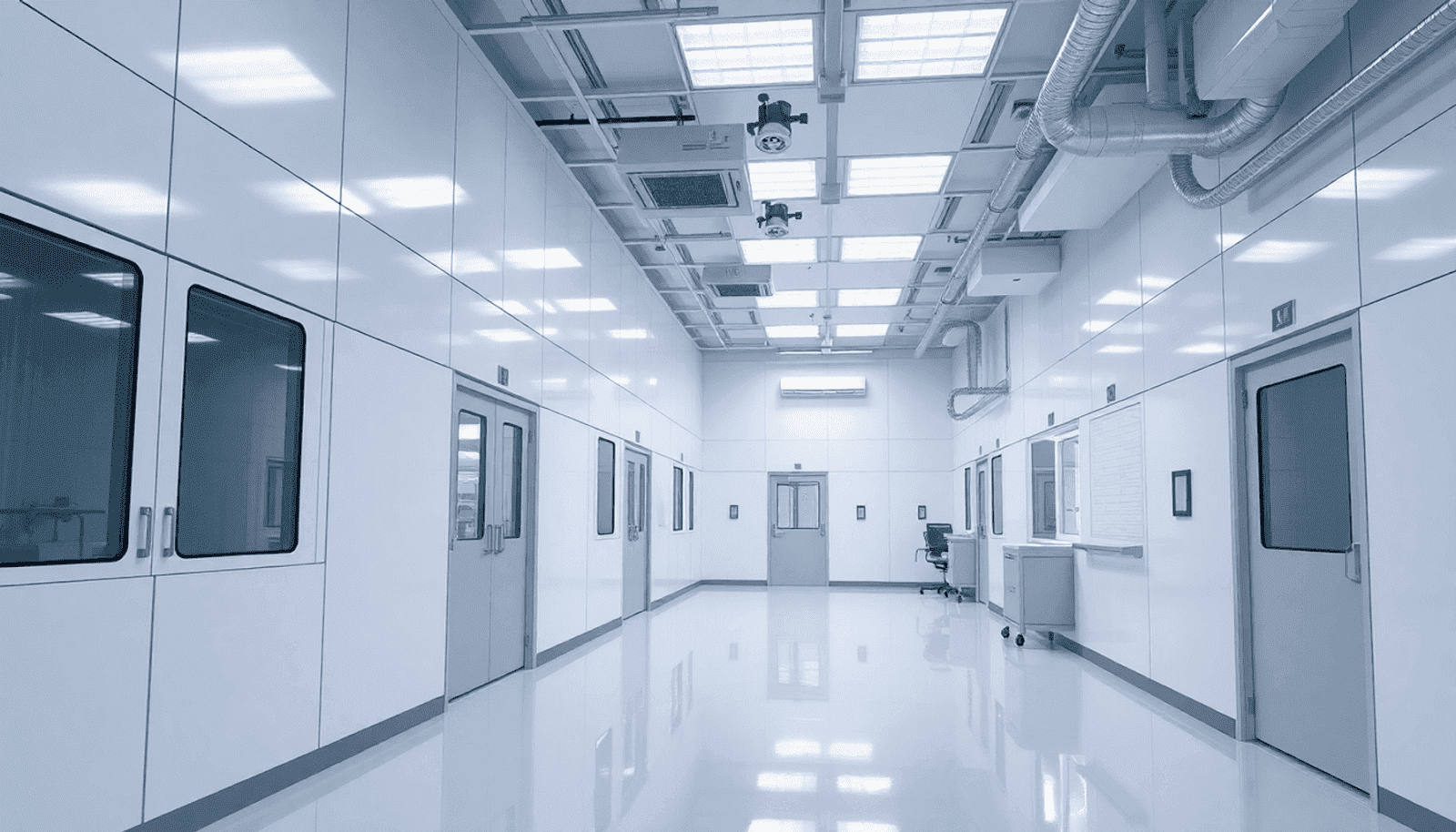

Modular Cleanrooms in Pharma: Fast-Track to Compliance

Learn how modular cleanrooms offer a fast, GMP-compliant solution for pharmaceutical manufacturing in 2025.

In 2021, a leading Indian CDMO landed a major international contract to manufacture a niche biologic. The only problem? The timeline was brutal. They had just 90 days to build a GMP-compliant facility. Traditional construction was out of the question. Their solution? A modular cleanroom.

Within weeks, prefabricated modules were delivered and assembled on-site, creating an efficient GMP-compliant fill-finish facility that adhered to strict regulatory standards. This new facility was validated for ISO 7 cleanrooms and Grade C operations, ensuring that all processes met rigorous pharmaceutical compliance requirements. The effective use of cleanroom technology and advanced cleanroom filtration systems allowed for optimal air quality and contamination control throughout the production process.

The facility passed inspection with flying colors, production commenced on time, and the company’s credibility skyrocketed. This isn’t a one-off success; modular cleanrooms are transforming how the pharmaceutical world approaches compliance, speed to market in pharma, and scalability.

This article explores the growing adoption of modular cleanrooms in pharma—how they work, their benefits, regulatory implications, and real-world applications. We’ll also cover essential considerations such as cleanroom classification ISO-5 to ISO-8 and tips for discovering how to prepare a site for modular or prefabricated cleanroom installation.

What Are Modular Cleanrooms?

Modular cleanrooms, also known as prefabricated cleanrooms, are self-contained clean environments designed to meet ISO and GMP standards. These factory-built cleanrooms differ from traditional cleanrooms that require months of civil construction; instead, they are prefabricated, shipped, and assembled rapidly on-site.

Key Features:

- Pre-engineered panels and modular walls

- Integrated HVAC systems and filtration systems in cleanrooms

- Standardized or customizable modular cleanrooms

- Easily scalable or relocatable

These systems can serve a variety of pharmaceutical needs—from sterile API handling to clinical trial batch production and even HPAPI containment—while ensuring effective cleanroom contamination prevention. By adhering to CGMP requirements, modular cleanrooms provide optimal temperature and humidity control in cleanrooms, making them essential for various processes.

Why Pharma is Moving Toward Modular Facilities

1. Speed to Market in Drug Development

In drug development, every day counts. Modular cleanrooms significantly reduce construction and validation timelines—often cutting GMP compliance timelines from 12–18 months down to 3–6 months. This accelerated speed to market in drug development is crucial for responding swiftly to public health needs.

2. Cost Efficiency of Modular Cleanrooms

With off-site fabrication and minimal on-site labor, modular cleanrooms enhance the cost efficiency of modular cleanrooms by reducing operational disruptions and capital expenditures in cleanroom construction by up to 30%. This allows pharmaceutical companies to allocate resources more effectively while maintaining high standards of quality.

3. Flexibility and Scalability in Cleanroom Design

Need a Grade C cleanroom now and an ISO 5 space later? Modular facilities offer unparalleled flexibility and scalability in cleanroom design, allowing for seamless reconfiguration, upgrades, or relocation. These reconfigurable cleanroom solutions are essential for industries with shifting demands, such as the defense industry and advanced therapy medicinal product (ATMP) manufacturing.

4. Global Regulatory Pressure in Pharma

Regulators now demand faster, traceable responses to public health needs—especially in vaccine production and oncology. The increasing global regulatory pressure in pharma makes modular systems indispensable; they help meet these demands head-on while ensuring compliance with stringent industry standards.

Additionally, modular cleanrooms equipped with features like HEPA filters for air quality control and precise temperature and humidity control in cleanrooms are vital for maintaining the integrity of sensitive processes across various sectors, including pharmaceuticals and biotechnology.

Embracing modular cleanroom applications across industries not only streamlines operations but also ensures that companies remain agile in an ever-changing regulatory landscape.

Use Cases: Where Modular Cleanrooms Fit in Pharma

1. Clinical Trial Manufacturing

Startups and biotech firms use modular cleanrooms to initiate GMP-compliant clinical batches without waiting for permanent facilities. These clinical trial manufacturing cleanrooms offer flexibility and compliance with strict cleanroom performance standards.

2. CDMO Capacity Expansion

Contract manufacturers often use modular setups for CDMO capacity expansion. These adaptable cleanrooms are ideal for short-term contracts or the production of niche molecules, allowing swift adjustments to changing demands.

3. Pandemic Response

During COVID-19, pandemic response cleanrooms were deployed globally to meet sudden spikes in vaccine and diagnostic production. The ability to quickly establish these modular cleanrooms ensured that facilities could adhere to GMP-compliant practices while scaling up production.

4. HPAPI Manufacturing

Modular systems allow isolation, air handling, and containment in cost-effective units, minimizing risk in handling potent compounds. This is particularly essential in HPAPI manufacturing containment, where strict adherence to safety protocols is vital.

These diverse modular cleanroom applications in pharma highlight the versatility and efficiency of modular designs in various critical processes. Whether addressing urgent public health needs or supporting complex manufacturing tasks, modular cleanrooms remain an indispensable asset in the pharmaceutical industry.

Design Considerations: What Makes a GMP-Ready Modular Cleanroom?

1. Wall & Ceiling Panels

GMP-ready modular cleanrooms use cleanroom wall and ceiling panels made from sandwich materials with PU or PIR cores and aluminum or stainless-steel finishes. These panels ensure easy cleaning and durability, which are essential for maintaining strict hygiene standards.

2. Flooring

Seamless vinyl flooring or epoxy resin floors are crucial in modular cleanrooms, providing slip resistance, static control, and protection against microbes. This is particularly important in industries like food processing, where contamination risks must be minimized.

3. HVAC Systems

Effective HVAC systems in modular cleanrooms are equipped with pre-engineered Air Handling Units (AHUs) that include HEPA filtration. These systems are designed to maintain precise pressure differences required by GMP regulations, ensuring a controlled environment.

4. Cleanroom Zones

Cleanroom zoning options allow for the construction of clearly defined Grade A to D zones within the facility. This includes airlocks, material pass boxes, and gowning rooms, all designed to facilitate proper workflow while preventing contamination.

5. Utility Integration

Utility integration in modular cleanrooms is streamlined through modules that are pre-fitted with essential utilities—compressed air, RO water, steam lines—based on customer specifications. This approach not only enhances efficiency but also simplifies cleanroom assembly and reassembly processes.

By considering these design elements, you can ensure that your modular cleanroom meets the highest standards of cleanliness and regulatory compliance while enjoying the benefits of modular cleanrooms over traditional construction methods.

Comparison of Modular and Traditional Cleanrooms in Pharma

This table outlines the key differences between modular and traditional cleanrooms in the pharmaceutical industry, highlighting aspects such as cleanroom build time, cost considerations related to CAPEX and OPEX, scalability options, and the importance of regulatory validation. Modular cleanroom configurations are designed to minimize operational disruption during installation while offering greater flexibility compared to their traditional counterparts.

Validation & Regulatory Considerations for Modular Cleanrooms

1. Pre-Validation

Many factory-tested modular systems cleanrooms are factory-tested and partially qualified (DQ/IQ) before shipment, reducing the on-site qualification burden. This pre-validation step is crucial in the modular cleanroom validation process.

2. Regulatory Acceptance

Regulatory agencies including the US FDA, EMA, and CDSCO accept modular cleanrooms, provided all GMP principles in modular cleanrooms are met—especially in:

- Contamination control in cleanrooms

- Personnel/material flow

- Environmental monitoring in modular facilities

3. Documentation

Manufacturers must maintain validation protocols (OQ/PQ), HVAC data, and cleanroom classification reports just as they would for traditional systems. This includes adhering to cleanroom air changes per hour requirements and ensuring that documentation aligns with regulatory considerations for modular cleanrooms.

By understanding modular cleanroom types and benefits, companies—especially CBD companies—can effectively implement rapid deployment cleanroom solutions while ensuring compliance with established guidelines like the CAP583 series.

Additionally, consider the use of HEPA-N-Seal negative pressure safety seals during assembly to maintain stringent safety standards. Gowning rooms should be integrated early in the process to ensure proper contamination control.

When planning your cleanroom, it's also important to assess specific applications by comparing hardwall and softwall modular cleanrooms. For industries requiring flexibility, mobile cleanrooms may be an ideal solution.

Case Snapshot: Fast-Track Compliance in Action

A European CDMO was contracted for mRNA vaccine component production by a global pharma client. Their existing plant lacked sterile space, prompting the need for accelerated cleanroom compliance. Instead of building from scratch, they installed a 200 sqm modular ISO 7 cleanroom with Grade B aseptic zones in just 14 weeks. This efficient cleanroom installation process not only passed inspection but also helped meet global vaccine demand and positioned the CDMO for new business opportunities.

The project showcased the cleanroom design flexibility required to accommodate ESD sensitive materials while ensuring strict cleanroom air pressure control. By finding customizable modular cleanroom solutions for unique needs, the CDMO effectively navigated the challenges associated with different ISO cleanroom classes and essential cleanroom components.

Future of Modular Cleanrooms

As the pharmaceutical industry shifts to decentralized manufacturing in pharma and personalized medicine, modular cleanrooms will become the norm, not the exception. Key future trends in modular cleanrooms include:

- AI-integrated environmental monitoring systems that enhance efficiency and compliance with cleanroom classification standards ISO and FED 209E

- Robotic cleanroom assembly techniques that streamline modular cleanroom construction processes

- Carbon-neutral modular designs that align with sustainability goals across the industry

These innovations are essential for adapting to the evolving demands of the sector while finding benefits of modular cleanrooms versus traditional construction methods.

Conclusion:

In the pharmaceutical industry, compliance delays can cost lives—or at least, contracts. This is why modular cleanrooms as a strategic advantage are becoming essential. These flexible cleanroom options allow companies to launch or scale GMP operations without waiting a year (or more).

Modular cleanrooms are no longer an experimental option. They are proven, regulator-accepted cleanroom solutions that offer a future-ready approach to contamination control in pharma. With their unique features like vertical flow modular cleanrooms and expandable modular cleanrooms, these facilities meet the demanding standards of various industries, including the semiconductor industry.

In a world that demands speed, flexibility, and precision—modular cleanrooms might just be the new gold standard. As companies explore industries that use modular and other types of cleanrooms extensively, understanding key aspects such as hard wall vs soft wall cleanrooms and learning about air filtration and handling in modular cleanrooms becomes crucial.

FAQs

Q1. What are modular cleanrooms and how do they meet pharma industry standards?

Modular cleanrooms are prefabricated, ISO/GMP-compliant cleanroom units that are assembled on-site. They serve various pharmaceutical needs including aseptic processing and clean API manufacturing by meeting stringent regulatory standards such as ISO classifications 5-8.

Q2. What advantages do modular cleanrooms offer over traditional cleanroom construction?

Modular cleanrooms provide faster construction and validation timelines (3-6 months versus 12-18 months), cost savings of approximately 30%, greater flexibility and scalability, lower CAPEX and OPEX, pre-engineered designs for easier GMP validation, and minimal operational disruption during installation or expansion.

Q3. In which pharmaceutical applications are modular cleanrooms commonly used?

Modular cleanrooms are widely used for clinical trial manufacturing, capacity expansion by CDMOs, pandemic response initiatives, high potency active pharmaceutical ingredient (HPAPI) manufacturing, and aseptic processing environments requiring strict contamination control.

Q4. How do regulatory bodies like FDA, EMA, and CDSCO view modular cleanrooms?

Regulatory authorities such as the FDA, EMA, and CDSCO accept modular cleanrooms provided they comply with GMP requirements and have thorough documentation demonstrating compliance. Modular cleanrooms can be validated to meet all necessary regulatory standards for pharmaceutical manufacturing.

Q5. What design considerations are critical when building a modular cleanroom for pharma use?

Key design elements include selecting appropriate wall and ceiling panels, flooring materials compatible with cleaning protocols, HVAC systems designed for contamination control, defining cleanroom zones (e.g., Grade B aseptic areas), and seamless integration of utilities to ensure compliance with GMP guidelines.

Q6. What future trends are shaping the development of modular cleanrooms in the pharmaceutical industry?

Emerging trends include integrating AI-enabled environmental monitoring systems for real-time contamination control, robotic assembly to enhance precision and speed of construction, and carbon-neutral designs focused on sustainability through reduced raw material usage and energy-efficient HVAC solutions.