by Ravindra Warang

7 minutes

Continuous Granulation Technology & Benefits

Discover continuous granulation in pharma—non-stop efficiency, real-time control, and faster scale-up for oral solid dosage lines.

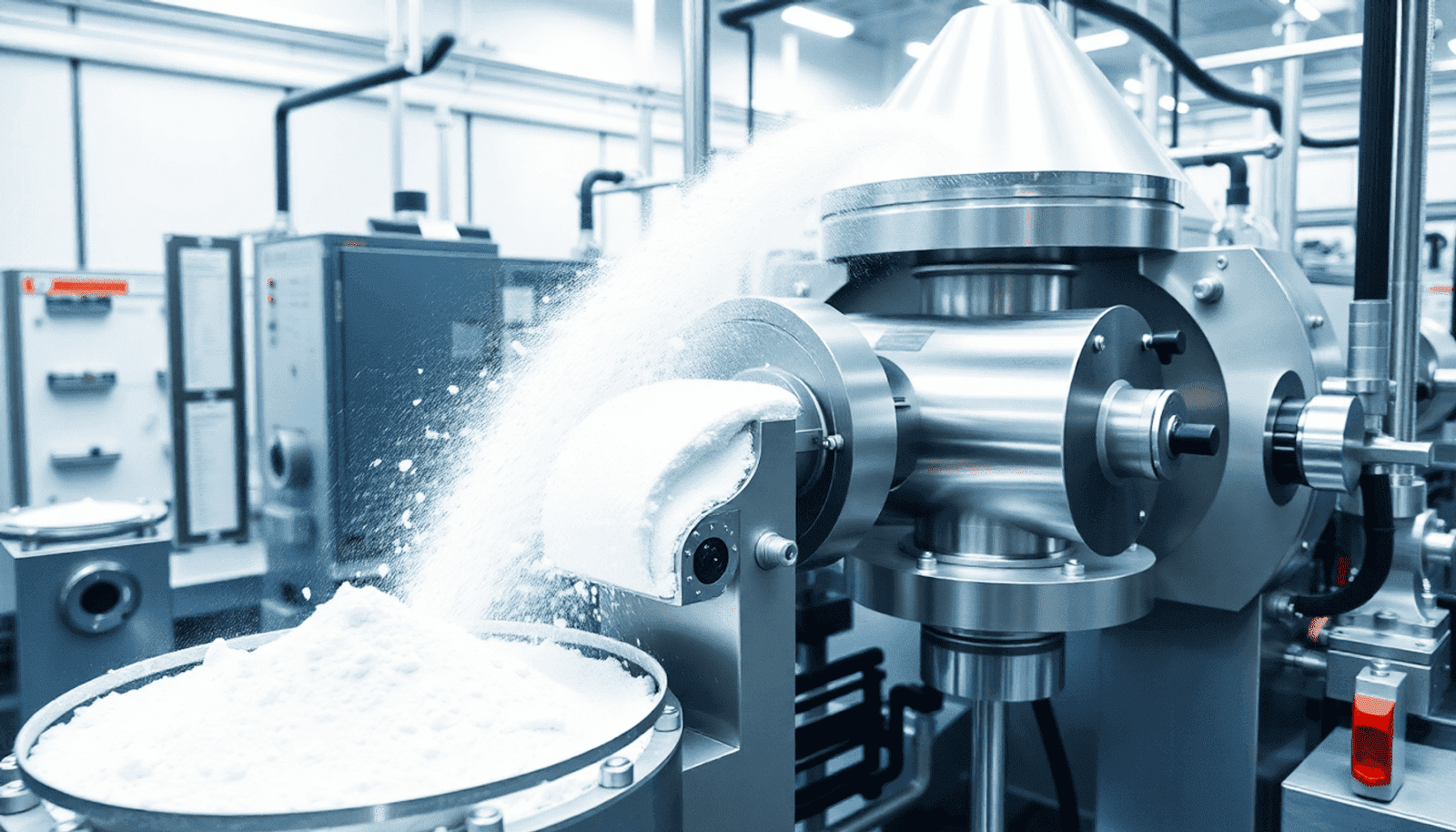

In a clean pharmaceutical facility in Switzerland, something quietly groundbreaking is happening. The granulation line hasn't stopped in 72 hours. No batch breaks. No idle time. Just a seamless flow of powders transforming into uniform, high-quality granules. Welcome to the era of continuous granulation—a technological leap that’s rewriting how oral solid dosages are made.

As regulatory demands tighten and cost pressures rise, pharmaceutical manufacturers are embracing continuous manufacturing not just as a buzzword, but as a business imperative. Continuous granulation technology is at the forefront of this shift, offering numerous continuous manufacturing benefits that enhance efficiency and ensure regulatory compliance in pharma.

In this article, we decode the science behind continuous granulation—exploring critical material attributes (CMA) like moisture content and particle density. We’ll also discuss how formulation development is evolving with these advanced processes, allowing for better control over parameters such as inlet air temperature and drying process control in granulation.

As we navigate the strategic benefits of continuous granulation, we'll provide pharma professionals with a clear roadmap to adoption, highlighting cost-effective manufacturing solutions that streamline operations from tablet dedusting and packaging processes to scaling up elimination.

What is Continuous Granulation?

Continuous granulation is a modern method that offers an alternative to traditional batch-based granulation. Unlike batch vs continuous granulation methods that process material in large, separate lots, this innovative approach runs non-stop. It allows powders to be fed, mixed, granulated, and dried in a steady, uninterrupted flow, making it ideal for process development in various industries.

Core Components Typically Include:

- Loss-in-weight feeders: These are essential for accurate material dosing, ensuring consistent input throughout the continuous granulation process.

- Twin-screw granulator: This component is crucial for intensive mixing and binder integration, effectively managing cohesiveness control during granulation.

- Continuous dryer (e.g., fluid bed): A key element for rapid, inline drying; fluid bed granination techniques are often employed to maintain product quality.

- In-line PAT tools: To monitor moisture, density, and size distribution in real time, these tools are vital for implementing real time release strategies.

- Automated control systems: These systems facilitate feedback and feedforward process optimization, ensuring adherence to the regulatory framework for continuous manufacturing.

Additional considerations such as the inlet air dew point and the use of Karl Fischer (KF) titrators for accurate LOD measurements are essential in maintaining quality throughout the process. Moreover, applying statistical experimental design in granulation drying can significantly enhance efficiency and product consistency.

Batch vs Continuous Granulation: A Quick Snapshot

This table highlights key differences in the batch granulation vs continuous granulation comparison, focusing on critical process parameters (CPP) that influence each method's efficiency and effectiveness. Consider factors like the quality target product profile (QTPP) when deciding between these granulation techniques.

How Does Continuous Granulation Work? Step-by-Step

1. Material Feeding

- In the continuous granulation workflow, APIs and excipients are fed using material feeding techniques such as gravimetric or loss-in-weight feeders.

- This ensures a consistent input ratio, reducing segregation and promoting uniform API distribution.

2. Twin-Screw Granulation

- Powders enter a twin-screw extruder, where the twin-screw extruder function plays a crucial role in mixing and agglomerating the blend.

- As the materials progress through the extruder, a binder (often aqueous) is injected to facilitate binder integration in granulation.

- The shear and kneading zones effectively mix the ingredients, ensuring proper agglomeration.

3. Drying Phase

- Wet granules pass through a continuous fluid bed dryer, part of the (semi-) continuous drying unit.

- During this fluid bed drying process, real-time moisture analysis is conducted to ensure endpoint accuracy and to assess the effect of dew point on drying efficiency.

4. Milling & Blending

- Dried granules are milled to size and optionally blended with lubricants, preparing them for subsequent tablet manufacturing processes.

5. Final PAT Checks & Discharge

- NIR/Raman sensors conduct PAT checks in granulation to validate CQAs like size, density, and moisture.

- This step is essential for gaining insights into process analytical technology applications in continuous manufacturing.

- Finally, the product is discharged for compression or encapsulation, all while maintaining a smaller production footprint and adhering to mini-batch production approaches.

Top 6 Benefits of Continuous Granulation

1. Real-Time Quality Assurance (QbD + PAT)

- Integrates Process Analytical Technology (PAT) such as NIR, Raman, and LIF sensors for effective granule moisture measurement.

- Enables design space optimization and proactive control through quality-by-design (QbD) principles.

2. Faster Scale-Up: Scale-Up Advantages

- No need for scale-dependent pilot trials, allowing for smoother transitions in the manufacturing process.

- Increase throughput by running the line longer—not larger—capitalizing on the scale-up advantages of continuous granulation.

3. Cost-Efficient Manufacturing: Cost-Efficient Manufacturing Practices

- Reduces operator hours, cleaning time, and changeovers, streamlining operations with cost-efficient manufacturing practices.

- Decreases material waste due to tighter process control, minimizing wet granulation water usage and ensuring dosing efficiency improvements.

4. Regulatory Readiness: Regulatory Readiness for Continuous Manufacturing

- Fully aligned with FDA’s Emerging Technology Program and ICH Q8-Q10, ensuring regulatory readiness for continuous manufacturing.

- Facilitates real-time release testing (RTRT), supporting compliance through robust process monitoring using fiber optic probes.

5. Smaller Facility Footprint: Smaller Facility Footprint

- Continuous systems like the ConsiGma™ system are compact and modular.

- Ideal for CDMOs, CMOs, and high-potency (HPAPI) environments while allowing for intermediate product storage elimination.

6. Seamless Integration with Continuous Tableting: Continuous Tableting Integration

- Output can directly feed into downstream compression units such as rotary tablet presses.

- Enables end-to-end continuous oral solid dosage manufacturing, linking granulation processes with efficient tableting integration.

Fact Check: Industry Adoption is Growing

According to a 2024 report by PharmTech, over 38% of top-50 pharma companies have implemented or are piloting continuous granulation lines as part of the broader industry adoption of continuous granulation. Notable pharmaceutical companies implementing continuous manufacturing include Pfizer, which is integrating advanced continuous granulation lines, and Johnson & Johnson, known for its innovative continuous platforms across various production suites.

Other industry leaders like GSK and Novartis are actively pursuing continuous manufacturing integration to enhance efficiency and ensure full traceability in pharmaceutical production. These companies are adopting sophisticated techniques such as roller compaction and employing microcrystalline cellulose (MCC) in their dry granulation processes.

Additionally, the use of soft sensors and inline real-time NIR measurement technologies is becoming crucial for granule size control and maintaining product quality. As the industry shifts towards a science and risk-based approach in drug development, understanding effects of processing parameters such as temperature and dew point on product quality becomes essential.

Collaboration with companies like DOW Chemical Company further supports these advancements, providing innovative solutions that streamline processes and ensure consistency across varied manufacturing environments.

Popular Technologies & Vendors in Continuous Granulation

This table highlights key players and technologies that are essential for continuous twin screw wet granulation processes in pharmaceuticals, emphasizing the importance of modularity and innovation in production methods.

Challenges to Consider Before Adopting Continuous Manufacturing Processes in Pharmaceuticals

1. Initial Capital Investment

The initial capital investment for equipment can be higher upfront than traditional batch systems. However, ROI is recovered through long-term efficiency gains and improvements in tablet tensile strength.

2. Change Management & Training

Effective change management is crucial as teams must shift from a batch mindset to a continuous mindset. This transition requires robust training programs and SOP redevelopment to ensure all team members are aligned with new processes.

3. Process Design Complexity

Continuous manufacturing involves significant process design complexity; it requires detailed material characterization and formulation studies. Understanding API-excipient interaction under dynamic flow conditions is essential for successful implementation. Additionally, one must consider screw configuration effects on the granulation process and address challenges in modeling low moisture content ranges.

4. Defining the Design Space

Proper design space definition is critical to ensure consistent quality and performance across batches. Utilizing PAT tools pharma can aid in real-time monitoring and adjustment of process parameters.

5. Equipment Selection and Integration

Selecting the right equipment, such as the Computrac® 1000 LOD Analyzer for moisture analysis, is vital for maintaining product integrity throughout the manufacturing process.

By carefully addressing these challenges, companies can successfully transition to continuous manufacturing and reap its numerous benefits.

Case Example: Novartis’ Continuous Manufacturing Unit

Novartis' continuous manufacturing unit in New Jersey has adopted a fully continuous line that integrates granulation, drying, blending, and compression—all under one PAT-driven SCADA system. This advanced facility utilizes technologies such as the GEA ConsiGma and the Orion Turbo 2 Karl Fischer titrator to ensure process stability monitoring and effective real-time release testing validated by the FDA.

The result of this innovative approach?

- Significant batch cycle reduction: from 2 days to under 6 hours

- 60% reduction in API waste: optimizing the use of active pharmaceutical ingredients (API)

- Real-time release testing validated by FDA: ensuring quality and compliance

By understanding continuous granulation processes and the equipment used, Novartis effectively manages the influence of raw material properties on granulation while maintaining high standards of efficiency and quality within its PAT-driven environment.

Is Continuous Granulation Right for You?

Ask yourself the following questions to evaluate whether continuous granulation is suitable for your pharmaceutical operations:

1. Are you manufacturing high-volume OSDs (Oral Solid Dosages)?

→ If yes, consider continuous granulation systems, which are optimized for high-throughput production.

2. Is real-time quality control a priority?

→ PAT (Process Analytical Technology) integration enables real-time quality monitoring. Using SIMCA-P software can further enhance data analysis and process control.

3. Are you working with moisture-sensitive APIs?

→ Twin-screw granulation systems allow precise moisture management during processing, protecting sensitive ingredients.

4. Do you need quick tech transfer or global rollout?

→ Modular platforms enable easier scale-up. A robust powder-to-tablet manufacturing line with a gravimetric feeding system and fluid-bed dryer streamlines tech transfer and supports global deployment.

Conclusion: From Reactive to Proactive Manufacturing

Batch manufacturing granulation served the pharmaceutical industry well for decades—but continuous granulation signals a significant reactive to proactive shift in manufacturing. This transition is not just about speed; it encompasses smarter compliance, real-time control, and reduced variability.

For innovators seeking speed-to-market, consistency, and regulatory harmony, the continuous granulation benefits are undeniable. As techniques like particle enlargement and pneumatic transfer in manufacturing become standard, methods such as LOD and exploring the use of near-infrared spectroscopy for inline quality control are essential.

Like a river that never stops flowing, your production line can now match the pace of innovation itself—thanks to advancements spearheaded by organizations like Syntegon and the CMAC consortium. Embracing these changes ensures that pharmaceutical manufacturing is not only efficient but also adaptive to ever-evolving regulatory landscapes.

FAQs (Frequently Asked Questions)

Q1: What is continuous granulation in pharmaceuticals?

Continuous granulation is a non-stop granulation process where powders are fed, mixed, granulated, and dried continuously without batch interruption. This method ensures consistent quality and efficiency, making it a key component of continuous manufacturing advantages in the pharmaceutical industry.

Q2: How does it differ from batch granulation?

In the batch granulation comparison, traditional batch granulation is stop-start with fixed quantities; in contrast, continuous granulation runs uninterrupted with scalable time-based output and real-time controls. This difference allows for better powder flow improvement and reduces variability in the final product.

Q3: What is the main advantage of continuous granulation?

The advantages of continuous granulation include:

- Faster scale-up

- Reduced variability

- Real-time quality control

- A smaller equipment footprint

Additionally, this process allows for effective blending of dried and milled granules and can be integrated with advanced techniques like near-infrared (NIR) spectroscopy for precise moisture measurement.

Q4: Is it FDA approved?

Yes. The FDA supports continuous granulation under its Emerging Technology Program and RTRT frameworks. This approval underscores the importance of innovation in pharmaceutical manufacturing processes.

Q5: Can it be integrated with tableting equipment?

Absolutely. Continuous granulation can seamlessly work with tableting equipment integration, ensuring that the entire production process remains efficient and consistent.

Q6: What is continuous granulation and how does it differ from batch-based granulation?

Continuous granulation is a non-stop pharmaceutical manufacturing process where powders are fed, mixed, granulated, and dried in an uninterrupted flow. Unlike batch granulation which operates in discrete, stop-start modes with limited batch sizes, continuous granulation offers scalable time-based output with real-time process controls and a more compact modular design.

Q7: What are the core components involved in a continuous granulation system?

A typical continuous granulation system includes loss-in-weight feeders for consistent material feeding, a twin-screw granulator for mixing and agglomeration with binder injection, a continuous dryer such as a fluid bed dryer equipped with real-time moisture analysis, in-line Process Analytical Technology (PAT) tools like NIR or Raman sensors for quality validation, and automated control systems to ensure seamless operation.

Q8: Which pharmaceutical companies have adopted or piloted continuous granulation technologies?

Over 38% of the top-50 pharmaceutical companies have implemented or are piloting continuous granulation lines. Notable adopters include Pfizer, Johnson & Johnson (J&J), GlaxoSmithKline (GSK), and Novartis—all leveraging this technology to enhance manufacturing efficiency and product quality.

Q9: What challenges should manufacturers consider when transitioning to continuous granulation?

Key challenges include the initial capital investment required for equipment acquisition, managing organizational change including staff training on new processes, and addressing process design complexity which demands detailed material characterization, formulation studies, and understanding API-excipient interactions to ensure robust operation.