by Mrudula Kulkarni

14 minutes

Breaking Pharma Silos: How Cross-Functional Alignment Determines Speed, Cost, and Trust

How cross-functional alignment drives speed, cost control, and trust in pharmaceutical organizations.

Pharmaceutical companies do not fail because they lack science. They struggle because science, manufacturing, quality, regulatory, commercial, and supply chain often operate as parallel universes.

Inside many organizations, brilliant teams work hard. R&D pushes molecules forward. Manufacturing optimizes throughput. Quality safeguards compliance. Regulatory negotiates approvals. Commercial plans launch strategies. Each function performs with discipline. Yet when misalignment creeps in, timelines stretch, costs escalate, and internal friction quietly erodes trust.

The industry calls it “complexity.” In reality, it is fragmentation.

Breaking pharma silos is no longer a cultural aspiration. It is a strategic determinant of speed to market, cost efficiency, regulatory confidence, and long-term stakeholder trust.

The Hidden Cost of Functional Silos

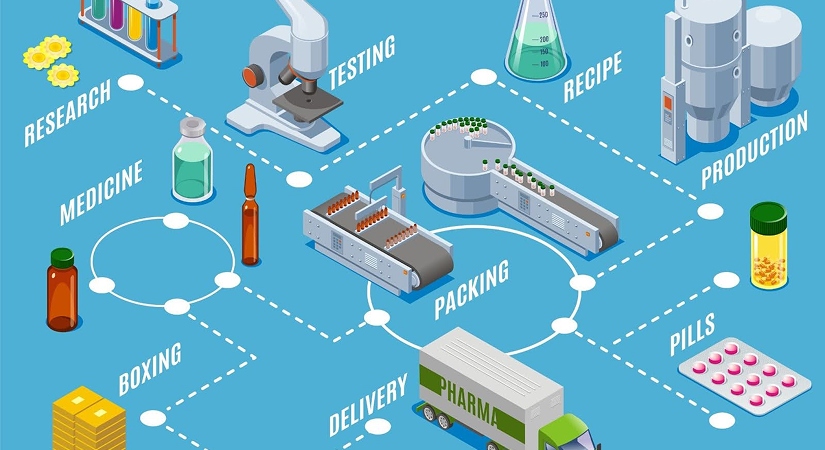

Pharmaceutical operations are inherently cross-functional. A single drug development program spans the entire pharmaceutical value chain, from drug discovery and clinical development to regulatory affairs, quality assurance, manufacturing and tech transfer, supply chain management, commercial strategy, and pharmacovigilance.

Each function plays a critical role in bringing a therapy to market. Yet despite this deep interdependence, most pharmaceutical organizations remain structured around functional silos. Performance metrics are optimized at the departmental level, incentives are locally defined, and data systems often operate in isolation, creating fragmentation across what should be an integrated process.

The result?

- Late-stage manufacturing changes that delay approvals

- Regulatory rework due to incomplete technical documentation

- Quality investigations triggered by poor cross-department communication

- Commercial forecasts misaligned with supply readiness

- Escalating COGS due to late process adjustments

The cost of silos rarely appears on financial statements as “organizational misalignment.” Instead, it shows up as extended development timelines, post-approval changes, warning letters, and lost competitive windows.

In an era where speed to market, GMP compliance, and supply chain resilience determine competitive advantage, functional isolation is no longer tolerable.

Speed: Alignment Determines Time to Market

Time-to-market in pharmaceutical development is not solely determined by clinical success. It is shaped by how early cross-functional dialogue begins.

When manufacturing is brought into development discussions late, scale-up challenges emerge during tech transfer. When the regulatory body is engaged only after data is generated, submission gaps appear. When quality is reactive instead of embedded in process design, deviations multiply.

Cross-functional alignment accelerates:

- CMC readiness

- Process validation planning

- Regulatory submission completeness

- Tech transfer timelines

- Commercial launch preparedness

Organizations that integrate development, manufacturing, quality, and regulatory from Phase II onward often compress submission timelines and reduce post-approval changes.

Alignment reduces rework. Rework is time.

In highly competitive therapeutic areas such as oncology, biologics, cell and gene therapy, and vaccines, even a six-month delay can translate into millions in lost revenue and diminished market positioning.

Cost: The Compounding Effect of Misalignment

Silos are expensive.

Consider the late discovery of process variability during scale-up. It often triggers a cascade of consequences, including additional validation batches, reworked documentation, increased regulatory queries, delayed commercial launches, and even inventory write-offs. What begins as a localized issue can quickly escalate into a chain reaction that affects timelines, costs, and market performance.

Or consider commercial over-forecasting without supply alignment. Excess production strains working capital and warehouse capacity.

Cost inefficiencies compound when:

Cross-functional alignment reduces the cost of poor quality (COPQ) and improves operational efficiency.

When quality, manufacturing, regulatory, and supply chain share visibility into risk, they reduce duplication and unnecessary conservatism while maintaining compliance rigor.

Alignment does not mean lowering standards. It means removing friction.

Trust: The Intangible That Determines Everything

Trust inside pharmaceutical organizations matters as much as compliance metrics.

When departments operate in silos, perceptions begin to distort collaboration. Quality may be viewed as an obstacle rather than a safeguard, regulatory may be seen as overly cautious instead of strategic, manufacturing may feel constrained by documentation requirements, and commercial teams may perceive operations as slow or unresponsive.

Over time, these narratives erode alignment and weaken trust across the organization. But when cross-functional alignment is strong, trust grows because decisions are transparent, risks are shared, and accountability is collective. External trust also depends on internal alignment.

Regulators notice when companies demonstrate:

- Cohesive contamination control strategies

- Consistent documentation across submissions

- Integrated deviation management

- Clear root cause analysis supported by cross-functional review

Alignment strengthens regulatory credibility.

Patients, partners, and investors trust organizations that demonstrate operational coherence.

Trust is not built in press releases. It is built in meeting rooms where science, quality, and business objectives align.

Why Silos Persist

If silos are so costly, why do they persist?

Because pharmaceutical companies are built on deep specialization. Functional expertise is necessary in a highly regulated environment. But specialization without integration breeds fragmentation.

Common drivers of silos in pharmaceutical organizations include legacy organizational structures that reinforce functional boundaries, departmental KPIs that reward local optimization over enterprise outcomes, and separate data platforms such as non-integrated ERP, LIMS, and QMS systems that fragment information flow.

Geographic dispersion of teams further complicates collaboration, while fear of regulatory scrutiny can foster excessive risk aversion, discouraging open cross-functional dialogue and shared decision-making.

Breaking silos requires structural and cultural intervention.

The Strategic Imperative of Cross-Functional Governance

High-performing pharmaceutical organizations implement cross-functional governance models that embed alignment into decision-making.

This includes:

- Cross-functional development councils

- Integrated product lifecycle teams

- Joint quality-manufacturing risk reviews

- Shared digital dashboards

- Enterprise-wide performance metrics

Instead of handing projects from one department to another, aligned organizations maintain continuity from development through commercialization.

They adopt a lifecycle mindset.

For example, integrating Quality by Design (QbD) principles early ensures that robust manufacturing is embedded in clinical planning. Aligning supply chain and regulatory teams during CMC documentation reduces submission gaps.

Alignment reduces surprises. In pharma, surprises are expensive.

Digital Integration as an Enabler

Breaking silos is not only cultural. It is digital.

Fragmented data systems amplify misalignment. When clinical data, manufacturing data, environmental monitoring records, and quality documentation live in separate platforms, collaboration slows.

Modern pharmaceutical companies are investing heavily in integrated Quality Management Systems (QMS), Enterprise Resource Planning (ERP) platforms, Laboratory Information Management Systems (LIMS), digital batch records, and real-time analytics dashboards to strengthen operational cohesion.

These digital transformation initiatives enhance data transparency, accelerate deviation investigations, enable real-time trending, facilitate shared risk assessments, and streamline regulatory documentation processes. While technology alone does not automatically eliminate organizational silos, it provides the essential infrastructure that enables alignment, visibility, and more informed cross-functional decision-making.

Cultural Reset: From Functional Ownership to Shared Accountability

True cross-functional alignment requires a cultural shift from “my department” to “our outcome.”

Leaders must redefine success metrics to include enterprise performance, not just departmental targets.

Examples include:

- Measuring time to batch release across quality and manufacturing

- Evaluating submission quality across regulatory and development

- Linking supply reliability to cross-functional forecasting accuracy

- Tying executive compensation to enterprise KPIs

When incentives align, behaviors follow.

Cross-functional workshops, shared risk reviews, and integrated planning sessions create institutional muscle memory for collaboration.

Alignment becomes habitual.

Case Pattern: Where Alignment Changes the Outcome

Across the industry, consistent patterns have become increasingly visible. Organizations that deliberately break down silos and foster cross-functional alignment tend to move with greater precision and confidence. Regulatory submissions are more complete and cohesive, leading to faster approvals and fewer post-approval supplements. Deviations are investigated holistically rather than in isolation, reducing the likelihood of repeat issues and strengthening root cause analysis.

Recall risk declines because manufacturing, quality, and supply chain operate with shared visibility into process variability and emerging trends. Inspections become less adversarial and more procedural, as regulators encounter consistent documentation and aligned narratives. Supply continuity improves because forecasting, production planning, and quality release decisions are coordinated rather than reactive.

In contrast, companies that maintain rigid functional boundaries often find themselves in cycles of remediation. Audit findings repeat because systemic issues remain unaddressed across departments. Costs escalate as corrective actions multiply and timelines stretch. High turnover in quality and operations roles reflects burnout from constant firefighting. Product launches are delayed due to last-minute technical or regulatory gaps, and commercial teams struggle to recover lost market windows. Over time, underperformance becomes normalized.

The difference between these trajectories is rarely scientific capability or technical expertise. Most organizations possess strong talent and infrastructure. What differentiates performance is organizational coherence, shared accountability, and the discipline to execute as an integrated enterprise rather than as a collection of high-performing but disconnected functions.

Cross-Functional Alignment in the Era of Complex Therapies

Advanced modalities such as biologics, mRNA platforms, and cell and gene therapies significantly magnify the need for cross-functional alignment because their scientific complexity extends far beyond traditional small molecules. These therapies rely on intricate manufacturing processes that are highly sensitive to variability, demanding tight control over raw materials, process parameters, and environmental conditions.

Many require strict cold chain logistics, where even minor temperature deviations can compromise product integrity. They operate under intense regulatory scrutiny, as agencies closely evaluate process robustness, comparability data, and long-term safety. In some cases, they have narrow therapeutic windows or are tailored to individual patients, making precision in production, release, and distribution essential.

In this environment, any disconnect between development, manufacturing, quality, regulatory, and supply chain introduces operational and compliance risk. A misaligned tech transfer can delay scale-up. Gaps in quality oversight can trigger investigations. Inaccurate demand forecasting can disrupt patient access. For personalized therapies, even minor coordination failures can directly impact treatment timelines.

As therapeutic innovation accelerates and products become more complex, organizational alignment is no longer a best practice. It is a structural requirement. Without integrated decision-making and shared accountability, complexity multiplies risk. With alignment, complexity becomes manageable and execution becomes reliable.

Breaking Silos: Practical Steps for Pharma Leaders

- Establish Integrated Lifecycle Teams

Ensure cross-functional representation from early development through post-approval.

- Align KPIs Across Functions

Replace local metrics with shared enterprise goals.

- Implement Unified Digital Platforms

Integrate QMS, ERP, LIMS, and regulatory systems for shared data visibility.

- Formalize Cross-Functional Risk Reviews

Create structured forums for joint risk evaluation.

- Model Alignment at the Executive Level

When leadership demonstrates integrated decision-making, the organization follows.

From Operational Efficiency to Strategic Advantage

Breaking pharma silos is not about soft collaboration rhetoric. It is about strategic execution.

Cross-functional alignment directly determines development speed, cost control, compliance strength, regulatory credibility, supply reliability, and overall market competitiveness. In a global pharmaceutical landscape defined by accelerated approvals, increasingly complex therapies, and rapid digital transformation, fragmentation becomes a strategic liability.

Alignment, by contrast, serves as leverage, enabling organizations to move faster, operate more efficiently, and build lasting trust with regulators and patients alike.

Final Thought

Cross-functional alignment shapes development speed, cost control, compliance strength, regulatory credibility, supply reliability, and market competitiveness because pharmaceutical success depends on coordinated execution. Timelines accelerate when R&D, manufacturing, regulatory, and quality collaborate early. Costs decline when risks are addressed collectively rather than surfacing late.

Compliance strengthens through shared documentation and aligned investigations. Regulatory confidence grows when decisions are coherent and scientifically consistent. Supply reliability improves when the commercial, production, and quality teams operate under a unified set of assumptions.

In a landscape defined by accelerated approvals, complex therapies, supply volatility, and digital transformation, fragmentation is a strategic liability. Alignment, by contrast, reduces rework, improves decision quality, shortens feedback loops, and reinforces accountability. It transforms complexity into coordinated action. In an industry where trust is earned through consistent performance, cross-functional alignment is not optional. It is a decisive advantage.

FAQs

1. Why are silos common in pharmaceutical organizations?

Pharma companies are built on deep specialization and regulatory complexity, which naturally leads to function-based structures and isolated KPIs.

2. How does cross-functional alignment improve speed to market?

Early integration between R&D, manufacturing, regulatory, and quality reduces rework, prevents submission gaps, and accelerates tech transfer and commercialization.

3. Does breaking silos compromise compliance?

No. Alignment strengthens compliance by ensuring consistent documentation, shared risk assessments, and cohesive contamination control strategies.

4. What role does digital transformation play in breaking silos?

Integrated systems like QMS, ERP, and LIMS enhance transparency, real-time data access, and collaborative risk management.

5. How can leaders initiate cross-functional alignment?

By aligning KPIs, forming lifecycle teams, integrating digital platforms, formalizing joint risk reviews, and modeling collaborative decision-making at the executive level.

20260219124626.svg)

20260219124804.svg)

20260219124844.svg)