by Ravindra Warang

7 minutes

Emerging Trends in Granulation 2025

Explore the top 2025 trends reshaping pharma granulation—from AI and twin-screw tech to green, scalable solutions.

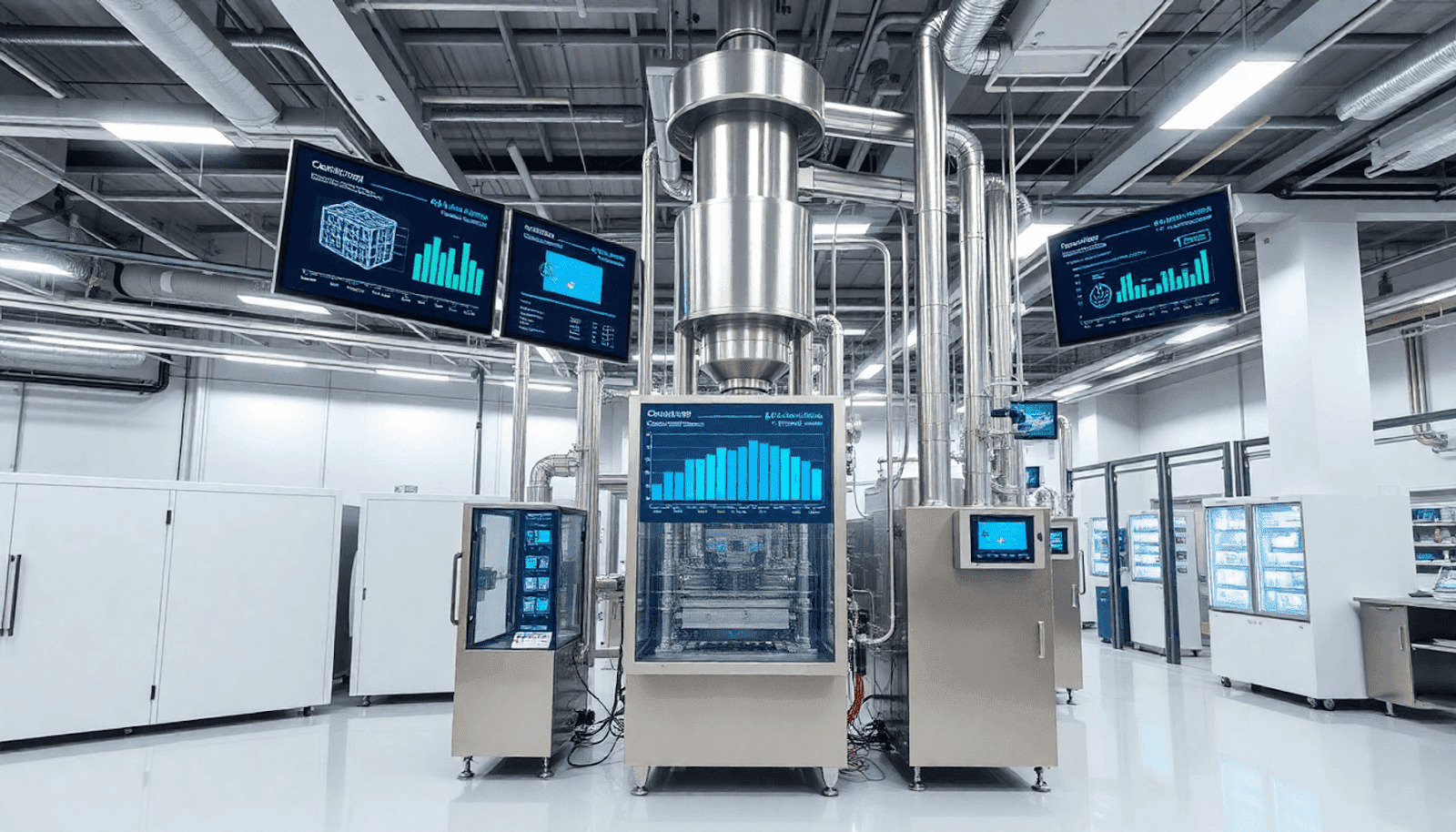

In a modern manufacturing facility in 2025, a technician monitors a twin-screw granulation line powered by AI. Real-time data on binder saturation, moisture content, and particle size is displayed on the screen, showcasing the use of smart automation in pharmaceutical granulation. There's no need for manual intervention or worry about batch errors—everything runs smoothly and continuously.

This may sound like something out of a science fiction movie, but it's actually the future of pharmaceutical granulation innovation. The industry is moving towards continuous manufacturing, sustainable granulation practices, and advanced AI-powered processes, leading to significant changes in the world of granulation.

In this article, we'll explore the top trends shaping the granulation industry in 2025 and discuss how pharmaceutical companies can stay ahead of the game.

1. Continuous Granulation Is Now the New Norm

Batch granulation vs continuous granulation is a crucial consideration for pharmaceutical manufacturers today. Batch granulation is no longer the default; instead, many are rapidly adopting continuous granulation systems to:

- Increase pharmaceutical manufacturing throughput and reduce downtime

- Ensure uniform product quality control in granulation processes

- Enable real-time quality control through process analytical technology (PAT)

Top adopters in 2025 include CDMOs adopting continuous granulation like Thermo Fisher, GEA, and Pfizer-led organizations.

Fact: Over 60% of new granulation lines commissioned globally in 2024-25 were continuous, up from 22% in 2019 (Source: PharmaTech Reports). This shift highlights the growing importance of sustainability and efficiency in the industry.

As the market evolves, regional market analysis across the Americas, EMEA, and Asia-Pacific will be essential to identify key market segments and growth opportunities within dry granulation equipment.

2. Twin-Screw Granulation Gains Momentum

Unlike traditional methods, twin-screw granulators combine feeding, mixing, and granulating into one streamlined process. This approach is particularly beneficial for QbD implementation and offers significant process flexibility in granulation.

Why It Matters:

- The compact footprint for granulation makes it ideal for small facilities.

- Twin-screw granulators are compatible with heat-sensitive APIs due to their short residence time, ensuring that delicate compounds remain stable throughout the process.

- Key Vendors: GEA (Consigma), Thermo Fisher, Leistritz, Chamunda Pharma Machinery Pvt. Ltd.

3. AI & Machine Learning in Granulation Optimization

AI in granulation optimization is transforming the pharmaceutical industry by leveraging advanced algorithms to enhance production efficiency. These technologies are now used to:

- Predict optimal binder concentrations through machine learning for binder concentrations, based on formulation behavior

- Identify failure patterns across batches, improving quality control and reducing OOS rates

- Auto-adjust impeller speeds, drying cycles, or feed rates in real time, facilitating real-time process adjustments in granulation

Tools in Use:

- Digital twins in pharmaceutical production to simulate full-scale production lines and assess granulation trends 2025

- AI-powered PAT dashboards that monitor critical parameters and ensure compliance with cGMP standards

Result: Reduced trial batches in granulation, lower OOS rates, and faster tech transfers.

By integrating these innovations, pharmaceutical companies like Freund-Vector Corporation are staying ahead in the competitive landscape roller compaction industry while ensuring sustainability practices and regulatory compliance in granulation equipment design.

4. The Rise of Green Granulation Technologies

Sustainability in pharmaceutical manufacturing is now a compliance goal, not a luxury. As the industry shifts towards greener practices, green granulation technologies are evolving to:

- Reduce energy consumption with innovations like low-temperature fluid bed dryers

- Eliminate solvents through solvent-free granulation methods such as melt granulation and steam granulation

- Minimize waste by implementing closed-loop systems in granulation

Green Alternatives Trending in 2025:

- Steam Granulation – Uses steam as a binder, effectively eliminating VOCs while promoting sustainability

- Foam Binder Systems – Reduce binder volume by 50% and lower drying time, enhancing efficiency in the granulation process

- Melt Granulation – Solvent-free method that utilizes meltable binders like PEGs, ensuring a safer and more sustainable production environment

As we approach 2025, understanding the biological roles of PDGF and TGFβ in granulation tissue formation will be crucial, especially in contexts related to hypertrophic scar formation and the role of TGFβ in wound healing. Additionally, staying informed about regional market dynamics across the Americas and trends such as United States Tariffs 2025 will be essential for companies like Gerteis Maschinen + Processengineering AG operating within the roller compactor market size 2024-2025-2030. Furthermore, integrating digital twin and machine learning in granulation processes can revolutionize efficiency and product quality while aligning with the overarching goals of sustainability.

5. Modular & Skid-Mounted Granulation Units

Smaller CDMOs and fast-scaling generics manufacturers need plug-and-play flexibility. This demand has led to the rise of modular skid-mounted granulation units that offer comprehensive solutions.

Trend: Prefabricated modular systems that:

- Combine granulation + drying + milling

- Fit into tight facility layouts

- Are relocatable and validation-ready granulation units

These innovative systems are essential for ensuring CDMO flexibility in granulation processes, allowing manufacturers to adapt quickly to changing demands.

Top Providers: IMA Active, ACG, Diosna, Hosokawa Micron Corporation

As the industry evolves, it's crucial to consider how factors like excessive granulation complications 2025 and advancements in roller compaction technology trends 2025 will impact the selection of these units. Additionally, exploring signalling pathways involved in wound healing relevant to granulation trends for 2025 can provide valuable insights for manufacturers looking to optimize their processes in North America and EMEA.

6. PAT Tools Are Becoming Standard in Pharmaceutical Granulation, Not Optional

The FDA's push for Quality by Design (QbD) compliance and real-time release testing (RTRT) is driving wider adoption of PAT tools in pharmaceutical granulation.

Common Tools in 2025:

- NIR Spectroscopy in moisture measurement – Measures moisture and binder content

- Raman Spectroscopy for blend uniformity – Checks blend uniformity

- Laser Diffraction for granule size distribution – Monitors granule size distribution

Impact: Granulation trends 2025 indicate that processes are now monitored and controlled with real-time analytics, reducing batch variability significantly. This shift is essential for ensuring consistent quality in products, especially those targeting complex biological pathways like Vascular Endothelial Growth Factor (VEGF) in growth factor signalling pathways in wound healing 2025.

As the industry evolves, it's crucial to identify complications caused by dysregulated growth factors leading to excessive granulation tissue during production. Techniques such as Dry Granulation using lab scale roller compactors are becoming increasingly popular in regions like Latin America and Asia-Pacific for dry granulation systems, enhancing dry granulation process efficiency across various sectors.

7. Smart SCADA & Remote Monitoring

In 2025, remote monitoring of GMP compliance is a reality. Smart SCADA systems in granulation processes now:

- Support cloud integration in SCADA systems

- Enable remote diagnostics for granulators and audits

- Provide historical trend analysis for maintenance to ensure preventive practices

Leading SCADA vendors in the pharmaceutical industry include Siemens, Emerson, and Allen Bradley. These advanced systems facilitate effective management of pharmaceutical formulations while enhancing supply chain resilience and dual sourcing strategies.

8. Precision Microgranulation for Pediatric & Geriatric Use

There’s rising demand for mini- and micro-tablets production, especially for age-specific populations such as those requiring pediatric and geriatric drug formulations. Granulation is adapting with advanced precision microgranulation techniques that ensure:

- Precision control of particle size below 200 microns

- Use of mini fluid bed processors in microgranulation

- Granulators with narrow PSD range control

Application: Dispersible tablets, sprinkle capsules, orally disintegrating granules (ODGs)

This evolution in granulation processes is crucial for developing effective medications that cater to the unique needs of these demographics, considering factors like the Haemostasis phase, Inflammation phase, and Proliferative phase in tissue healing. Additionally, understanding conditions such as Idiopathic pulmonary fibrosis (IPF) can guide the formulation of drugs that address specific symptoms while ensuring proper dosage accuracy through techniques like oscillating granulators.

As the industry grows, it's essential to assess competitive landscape and aftermarket service trends for dry granulation machinery, particularly in regions like the Middle East & Africa (EMEA). Companies like Kevin Process Technologies Pvt. Ltd. are at the forefront, integrating closed-loop fines recovery systems to enhance efficiency and comply with regulatory influences on granulation equipment.

Furthermore, healthcare professionals should learn about clinical applications addressing excessive granulation including steroid use and Mitomycin-C to optimize treatment outcomes effectively.

9. Integration of Granulation with Coating & Compression

In 2025, turnkey systems in pharmaceutical manufacturing no longer treat granulation as an isolated process. These advanced systems now integrate:

- Granulation

- Drying

- Compression

- Film coating

This integration of granulation with coating and compression offers several benefits:

- Seamless process control in granulation

- Faster changeovers in production

- Reduced validation cycles for integrated systems

Key integrators of granular technology such as Fette Compacting, IMA Active, and GEA are at the forefront of these granulation trends 2025. As the industry evolves, understanding the molecular mechanisms underlying fibrosis and scar formation related to granulation processes becomes crucial, especially in applications like the wound healing process.

Additionally, specialty chemicals play a vital role in enhancing the efficiency of these integrated systems across the Asia-Pacific market.

10. Granulation-as-a-Service (GaaS)

Contract development and manufacturing organizations (CDMOs) are offering Granulation-as-a-Service (GaaS) by providing dedicated granulation lines that include essential services such as formulation assistance in GaaS, tech transfer and scale-up services.

Why It’s Growing:

- Facilitates CapEx reduction for startups by minimizing initial investment costs

- Ensures GMP readiness from Day 1, allowing for compliant production processes

- Offers flexibility in capacity planning to adapt to changing market demands

Key providers include Piramal Pharma Solutions, Lonza, and Thermo Fisher CDMO Services, which are at the forefront of integrating Industry 4.0 technologies into their batch processing systems.

Additionally, as the demand for advanced therapeutic interventions for abnormal granulation tissue increases by 2025, staying informed on the latest research insights—such as those reviewing PDGF receptor blockers like olaratumab for future treatment options—will be crucial for stakeholders in this sector.

Conclusion: The Granule Revolution 2025 Is Here

Granulation isn't just changing—it's completely transforming. In 2025, with the emergence of smarter and more environmentally friendly granulation technologies, it is becoming more integrated than ever before.

From AI-powered continuous lines to modular skid systems, and from melt granulation innovations to twin-screw technology advancements—every innovation redefines what's possible in oral solid manufacturing.

As the pharmaceutical industry trends shift towards precision, scalability, and sustainability in roller compaction design and materials, granulation remains the key to maintaining quality. Those who adapt to these trends today won't just meet regulations—they'll take charge.

Welcome to the granule revolution.

FAQs

Q1: What is twin-screw granulation, and why is it important?

It’s a continuous granulation method combining mixing and granulation in one step, offering precise control and scalability. This twin-screw granulation explanation is essential for understanding how it enhances efficiency in drug manufacturing processes.

Q2: Are green granulation methods gaining popularity?

Yes, green granulation methods overview indicates that steam and melt granulation are rising due to sustainability mandates, lower energy use, and solvent-free processing. These methods align with the industry’s shift towards environmentally friendly practices.

Q3: What role does AI play in granulation?

AI role in granular optimization includes predicting binder volumes, adjusting process parameters in real time, and reducing trial batches using machine learning models. This technological advancement is crucial for staying ahead in the evolving landscape of 2025 pharmaceutical granulation trends.

Q4: What are the key granulation trends expected in 2025?

Key granulation trends in 2025 include continuous adoption of continuous granulation, increased use of twin-screw granulators, AI optimization for process control, implementation of green technologies, modular and skid-mounted units, PAT standardization with tools like NIR and Raman spectroscopy, remote monitoring via smart SCADA systems, precision microgranulation for specialized populations, integration with coating and compression processes, and the emergence of Granulation-as-a-Service (GaaS).

Q5: How is continuous granulation transforming pharmaceutical manufacturing?

Continuous granulation is enhancing pharmaceutical manufacturing by increasing throughput and improving quality control. Notably, over 60% of new production lines commissioned in 2024-25 utilize continuous granulation technology, a significant rise from 22% in 2019. This shift enables more efficient processing and consistent product quality.

Q6: What advantages do twin-screw granulators offer in granulation processes?

Twin-screw granulators combine feeding, mixing, and granulating into a compact unit ideal for small facilities. They are particularly suitable for heat-sensitive APIs due to controlled processing conditions. Their compact design facilitates space-saving layouts while maintaining effective granulation performance.

Q7: How is artificial intelligence (AI) being utilized to optimize granulation?

AI is leveraged to predict optimal binder concentrations and identify potential failure patterns during granulation. It dynamically adjusts impeller speeds, drying cycles, and feed rates to optimize the process. This reduces trial batches, out-of-specification (OOS) rates, and streamlines technology transfers, enhancing overall efficiency.

Q8: What is Granulation-as-a-Service (GaaS) and how does it benefit pharmaceutical companies?

Granulation-as-a-Service (GaaS) is a contract development offering that provides formulation assistance, technology transfer support, and scale-up services. GaaS helps pharmaceutical companies reduce capital expenditure (CapEx) burdens while ensuring Good Manufacturing Practice (GMP) readiness through expert-managed granulation solutions.