by Enoch Daniel

5 minutes

Pharmaceutical Blister Packaging: Benefits and Applications

Explore the benefits and applications of blister packaging in the pharma industry, ensuring product integrity, safety, and convenience.

Over the years, various packaging technologies have been developed and employed in the pharmaceutical industry. Considering the sensitivity of pharmaceutical products to environmental factors, appropriate packaging is necessary to ensure the product retains all its qualities before the intended patient finally uses it.

The first packaging materials used for pharmaceutical drugs were clay, natural fibers, stoneware, paper, and animal hides. Over time, these materials were replaced by glass bottles and ampoules.

After the invention of plastic in the 1900s, glass was replaced by plastic. Even today, most pharmaceutical products come in plastic packaging because it is versatile, lightweight, durable, and non-reactive with almost all medications.

From simple plastic bottles to plastic and aluminium blister packs, plastic packaging is used in various forms to protect pharmaceutical products. This article discusses one such plastic packaging that we, today, are most familiar with: the blister packaging in the pharmaceutical industry.

What is Blister Packaging?

Pharmaceutical blister packaging, commonly known as blister packs, comprises pre-formed cavities or packets usually made from thermo-formed plastic and backed by a paperboard, aluminium foil, or a plastic sheet. The plastic cavities and backing are sealed via heat bonding to secure the product inside the cavities.

Blister packs are used to package pharmaceutical products, consumer goods, and foods sensitive to environmental factors like humidity and contamination. However, blister packs are most commonly used in the pharmaceutical industry for tablets, pills, and capsules.

As blister packs are primarily plastic-based, there's growing pressure to adopt more eco-friendly alternatives in line with green pharmaceutical practices. Explore how the industry is advancing toward sustainable pharma packaging.

How is Pharmaceutical Blister Packaging Made?

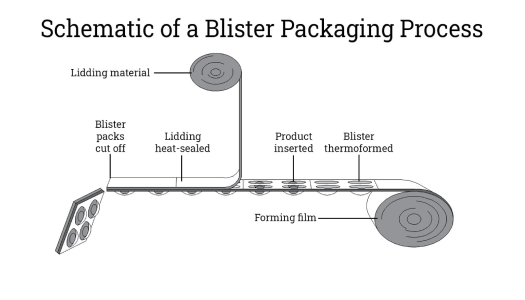

Pharmaceutical blister packaging is made via a multi-step process. While the exact manufacturing process depends on the materials used and application, here is a basic overview of the manufacturing process of blister packs:

Step 1: Material selection

The first step is material selection. Plastic films are used for thermoforming processes. Generally, polyvinyl chloride (PVC), polyvinylidene chloride (PVDC)-coated PVC, or polyethylene terephthalate (PET) are used in the thermoforming process. Aluminum foils are used for cold-forming processes. The lidding or backing material used is most typically an aluminum foil.

Step 2: Forming blister cavities

In the thermoforming process, the plastic film is heated to a specific temperature (depending on the film material) to make it malleable. Then, the heated film is shaped into cavities of desired sizes using vacuum/pressure molding.

In the cold-forming process, the aluminum foil is directly pressed into a mold to form cavities. Only mechanical force is used to form the cavity-like shape on the aluminum foil, without any heat, as this preserves the properties of aluminum.

Step 3: Filling the cavities

The formed cavities in the plastic or aluminum foil are then filled with the drug. Most often, tablets, pills, and capsules are filled in pharmaceutical blister packs. All cavities are filled using automated systems to ensure there is no human contact and contamination.

Step 4: Sealing

After the cavities are filled, the backing or lidding material (i.e., aluminum foil) is sealed using heat and pressure. The sealing process is also automatic to ensure the packaging is airtight and even.

Step 5: Final touches

Once the sealing is complete, the sealed strips are cut into individual blister packs with the desired number of tablets, for example, 8×2 and 4×4. Perforations are added so that individual doses can be easily separated.

The individual blister packs are labelled with branding information, packaging date, expiration date, and any other necessary information. Finally, they are inspected for deformities, missing tablets, and improper sealing before being boxed and distributed.

Benefits of Blister Packaging

Over the years, pharmaceutical blister packs have become the most popular method of packaging materials. Of course, this is because of their numerous benefits.

Blister packs are more than just a neat way to package pills; it is a popular choice in the pharmaceutical world, and for good reason. Blister packs combine safety, simplicity, and efficiency, making them a go-to solution for modern medication packaging.

Here’s why it stands out:

- Product Safety & Integrity: Airtight seals protect each dose from moisture, air, and contamination, ensuring the medication stays effective until use.

- Tamper-Evident: The sealed design makes it easy to detect any tampering. If the foil is broken, it’s clear the pack’s been opened.

- Dosing Compliance: With each pill individually sealed, it’s easier for patients to track doses, avoid mistakes, and stay on schedule.

- Cost-Effective: Lightweight and simple to produce, blister packs are cheaper to manufacture and transport compared to bottles.

- Accurate Tracking: Caregivers and patients can quickly count empty cavities to monitor how much medication has been taken.

What are Smart Blister Packs?

Smart blister packs are high-tech medication packages designed to help people take their medicine correctly and on time. Each dose sits in its own compartment, and built-in sensors track when a pill is taken. Smart blister packs make it easier to manage medications and improve health with fewer slip-ups.

How They Help:

- Reminders: They can beep or send alerts to remind you when it’s time for your meds.

- Tracking: They log every dose, so your doctor knows if you're staying on track.

- Insights: The data helps doctors spot patterns and adjust treatment if needed.

- Safety: They reduce the chance of missed or wrong doses, keeping you safer.

Eco-Friendly Blister Packaging Trends

To support a greener approach, the pharma industry is changing its packaging practices for medicines. Blister packaging in pharma is now being redesigned to be more environmentally friendly, reduce waste and be simpler to recycle.

Blister packaging is progressing, aiming to care for both individuals and nature. Made from better items, created with new ideas and powered by modern technology, the upcoming blister packaging is more efficient, eco-friendly and useful than before.

Here's a look at the eco-friendly trends shaping the future of blister packs:

1. Smarter, Greener Materials

Traditional PVC is being swapped out for more recyclable options like PET and PP plastics that can actually make it through recycling systems. Some companies are going even further, experimenting with plastics made from plants instead of petroleum. Blisters made from just one type of plastic are easier to recycle and reduce environmental impact.

2. Sustainable from Start to end

Designs now consider what happens after use, making it easier to recycle the entire pack. The Eco-Friendly Printing Inks and printing methods are shifting to greener options with fewer chemicals.

Manufacturing processes are being streamlined to consume less power. From factory to pharmacy, companies are working to reduce transportation-related carbon emissions, moving towards Greener Supply Chains

3. Tech Meets Sustainability

QR Codes & NFC Tags are smart features that don’t just give you product info or coupons, they reduce the need for extra leaflets or packaging.

A quick scan can offer patients guidance, support, and reminders, making packaging smarter and more useful with a better engagement rate.

4. New Packaging Frontiers

Some brands are testing out blister packs made with paper instead of plastic, a renewable, recyclable alternative. Another is Cold Form Packing offers high-level protection for sensitive meds while still allowing for more sustainable materials. Tech-enhanced smart blister packs with RFID or NFC can track doses and help patients stick to their treatment plans.

Applications of Blister Packaging

Here are some common blister packaging applications:

- Pharmaceutical industry: Blister packing technologies are commonly used for packing over-the-counter medications and single-dose medications. As one of the most widely used primary pharmaceutical packaging technologies, blister packs are preferred for packaging most tablets, pills, and capsules due to their ability to ensure product quality and prevent tampering during transportation.

- Consumer goods: Other types of blister packs are also used to package toys, hardware, and electrical items. However, instead of aluminum backing, cardboard or paperboard backings are used. The plastic is usually transparent so that the consumer can visually inspect the product before purchasing it.

- Foods: While blister packs are not very commonly used in the food industry, they are also used for some common food products like Jell-O and Lunchables. They are also used to separate individual chocolates or frozen cubes to ensure they retain their nutrition, quality, shape, and colour before consumption.

Bottom Line

Pharma blister packaging continues to evolve as a smart, safe, and sustainable solution in the pharmaceutical industry. From protecting sensitive drugs to ensuring patient adherence, the benefits of blister packaging are clear. Innovations in blister packaging materials for pharmaceutical products are making it more eco-friendly and efficient than ever.

With features like tamper-evidence, smart tracking, and improved recyclability, the advantages of blister packaging extend across patient safety, manufacturing, and sustainability. The importance of pharmaceutical packaging in delivering safer, more effective healthcare worldwide.

FAQs

1. What are the types of blister packs?

Blister packs are generally divided into thermoformed blister packs and cold-formed blister packs, as per the manufacturing process used to prepare them.

2. Can blister packs be recycled?

Blister packs are made of mixed materials (plastics and aluminium). Therefore, they cannot be directly recycled. While there has been research into recyclable blister packs, there are no options widely used in the market.

3. Why is blister packaging preferred in pharma?

Blister packs protect medications from moisture, light, and contamination, while making dosing easier and safer. They’re tamper-evident, cost-effective, and help improve patient adherence.

4. What are the latest innovations in blister packaging?

New trends include recyclable and bio-based materials, paper-based blisters, smart packs with RFID/NFC, and compact, eco-friendly designs that reduce waste and improve sustainability.