by Ravindra Warang

5 minutes

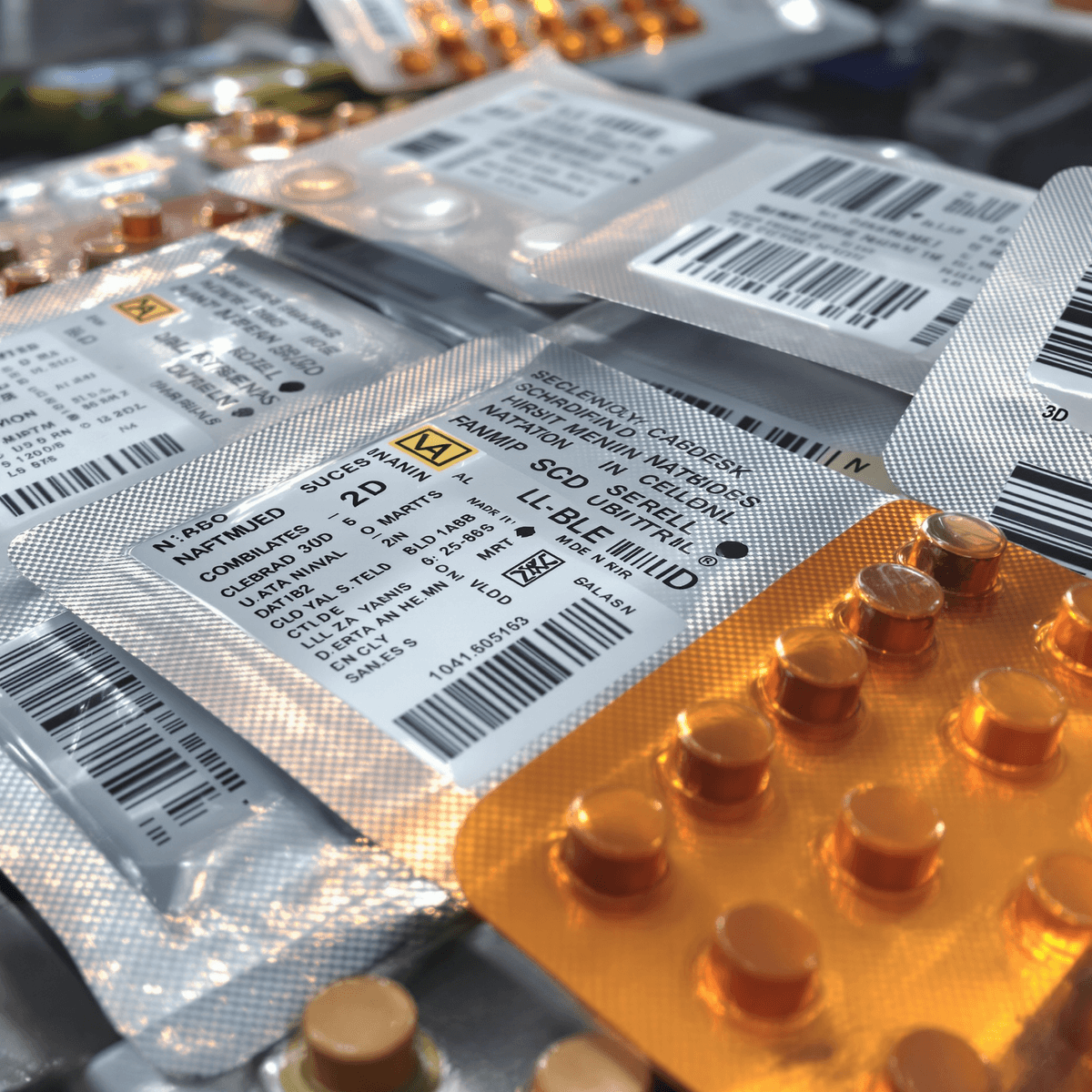

Serialization in Blister Packaging: How to Achieve Global Traceability

Learn how serialization in blister packaging assures global traceability, regulatory compliance, and safeguards pharmaceutical supply chains.

The pharmaceutical industry faces a critical challenge: ensuring product authenticity and traceability across global supply chains. Serialization in blister packaging emerges as a powerful solution to this challenge, providing a robust framework for tracking medications from production to patient.

This comprehensive guide explores:

- Advanced serialization techniques for pharmaceutical packaging

- Implementation strategies for blister packaging lines

- Integration of aggregation systems for enhanced traceability

- Regulatory compliance requirements and security measures

- Future trends in pharmaceutical track-and-trace technology

By mastering serialization in blister packaging, pharmaceutical companies can:

- Prevent counterfeit medications

- Enable rapid product recalls

- Maintain supply chain integrity

- Meet global regulatory standards

- Protect brand reputation

Ready to transform your pharmaceutical packaging operations? Let's dive into the essential components of successful serialization implementation.

Understanding Serialization and Aggregation Techniques in Blister Packaging

What is Serialization?

Serialization in pharma packaging creates a unique digital identity for each product unit. This identity takes the form of:

- Serial Numbers: Unique codes assigned to individual blister packs

- 2D Data Matrix: Machine-readable codes containing product information

- Human-Readable Text: Printed information for manual verification

The tracking process begins at the manufacturing line, where specialized cameras capture and verify these identifiers. Each blister pack receives its unique code, enabling real-time monitoring through the supply chain.

What is Aggregation?

Aggregation builds upon serialization by creating parent-child relationships between packaging levels:

- Primary Level: Individual blister packs

- Secondary Level: Cartons containing multiple blisters

- Tertiary Level: Shipping cases

- Pallet Level: Multiple cases grouped for transport

This hierarchical structure allows pharmaceutical companies to:

- Track product location at any point

- Verify authenticity instantly

- Detect unauthorized distribution

- Manage recalls efficiently

The system records every movement and transaction through secure databases. When a product changes hands, its status updates automatically. This creates an unbroken chain of custody from production to patient.

Benefits of Advanced Aggregation Systems

Advanced aggregation systems can handle:

- Multiple pack formats

- Variable batch sizes

- Different market requirements

- Cross-border shipments

These capabilities make serialization an essential tool for pharmaceutical manufacturers seeking global market access while maintaining compliance with regional regulations. Furthermore, as highlighted in this report on centralized traceability approaches, the integration of advanced aggregation systems with centralized traceability can significantly enhance supply chain transparency and efficiency.

Implementing Effective Serialization Solutions in Blister Packaging Lines

Successful serialization implementation in blister packaging requires a sophisticated integration of hardware and software components. Here's a detailed breakdown of essential system elements:

Hardware Infrastructure

- Industrial PCs with redundant backup systems

- High-resolution cameras for code verification

- Precision lighting units for accurate inspection

- Touch screen displays for operator interface

- Label printers for serial number application

Software Components

- Proprietary serialization algorithms

- Real-time control systems

- Print management software

- Vision system integration

- Data management and storage solutions

The hardware setup creates a robust physical infrastructure where industrial PCs serve as the central nervous system, coordinating all serialization operations. These computers connect to high-resolution cameras that capture and verify each unique identifier with exceptional accuracy. Precision lighting units ensure optimal conditions for code reading and verification.

The software layer manages the generation, application, and verification of serial numbers. Advanced algorithms handle complex tasks such as:

- Serial number generation and validation

- Print quality inspection

- Data matrix code verification using guidelines like those provided in the GS1 DataMatrix Guideline

- Integration with enterprise systems

- Real-time production monitoring

These integrated systems work in harmony to maintain serialization accuracy at production speeds up to 210 blisters per minute while ensuring compliance with global traceability standards.

To enhance the effectiveness of these serialization solutions, leveraging technologies such as Machine Vision AI can significantly improve part identification and recognition processes. Furthermore, adopting advanced data management practices, as discussed in this research article, can optimize data handling and storage solutions within the serialization framework.

Design Considerations for Blister Packaging Lines with Serialization Capabilities

Modern blister packaging lines must accommodate diverse material combinations and package sizes while maintaining serialization accuracy. The design architecture integrates specific elements to handle:

Material Flexibility

- PVC (Polyvinyl Chloride) - Standard thermoforming material

- PVDC (Polyvinylidene Chloride) - Enhanced moisture barrier

- Aluminum combinations - Maximum protection against environmental factors

Critical Design Elements

- Adjustable forming stations for different blister depths

- Precision tablet/capsule feeding systems

- High-speed sealing mechanisms

- Integrated vision systems for quality control

- Implementation of advanced automation technologies to streamline operations

The blister packaging process follows a systematic flow:

- Material Feeding - Raw material rolls are loaded and aligned

- Thermoforming - Heat application creates precise cavity formations

- Product Loading - Automated systems place products into cavities

- Sealing - Lidding material application and heat-sealing

- Die Cutting - Individual blister separation

- Serialization Application - Unique identifier printing and verification

The line design must maintain speeds up to 210 blisters per minute while ensuring accurate serialization. Advanced sensor systems monitor material tensions, temperatures, and seal integrity throughout the process. Modular components allow quick changeovers between different product specifications without compromising serialization accuracy or production efficiency.

Ensuring Compliance and Security through Serialization and Aggregation Benefits

Serialization and aggregation create a robust framework for regulatory compliance across global pharmaceutical markets. These systems enable manufacturers to meet stringent requirements set by:

- FDA's Drug Supply Chain Security Act (DSCSA)

- European Union's Falsified Medicines Directive (FMD)

- China's Drug Administration Law

- Brazil's National Control System (SNCM)

The implementation of serialization in blister packaging strengthens supply chain security through:

- Real-time product authentication

Design Considerations for Blister Packaging Lines with Serialization Capabilities

- Modern blister packaging lines must accommodate diverse material combinations and package sizes while maintaining serialization accuracy. The design architecture integrates specific elements to handle:

Material Flexibility

- PVC (Polyvinyl Chloride) - Standard thermoforming material

- PVDC (Polyvinylidene Chloride) - Enhanced moisture barrier

- Aluminum combinations - Maximum protection against environmental factors

Critical Design Elements

- Adjustable forming stations for different blister depths

- Precision tablet/capsule feeding systems

- High-speed sealing mechanisms

- Integrated vision systems for quality control

- Implementation of advanced automation technologies to streamline operations

- The blister packaging process follows a systematic flow:

- Material Feeding - Raw material rolls are loaded and aligned

- Thermoforming - Heat application creates precise cavity formations

- Product Loading - Automated systems place products into cavities

- Sealing - Lidding material application and heat-sealing

- Die Cutting - Individual blister separation

- Serialization Application - Unique identifier printing and verification

- The line design must maintain speeds up to 210 blisters per minute while ensuring accurate serialization. Advanced sensor systems monitor material tensions, temperatures, and seal integrity throughout the process. Modular components allow quick changeovers between different product specifications without compromising serialization accuracy or production efficiency.

- Instant verification of product location

- Automated detection of counterfeit products

- Rapid response to suspicious activities

Brand protection benefits extend beyond regulatory requirements. As noted in a case study by Thermo Fisher Scientific, serialization not only aids in regulatory compliance but also provides defensible data traceability which is crucial for brand protection.

"Serialization creates a digital fingerprint for each product unit, making unauthorized replication virtually impossible and ensuring authentic products reach consumers."

The integration of serialization data with track-and-trace systems enables:

- Precise batch recall management

- Enhanced inventory control

- Detailed supply chain analytics

- Reduction in product diversion

These capabilities create a transparent supply chain ecosystem where stakeholders can verify product authenticity at any point. The collected data provides valuable insights into distribution patterns, helping manufacturers optimize their supply chain operations while maintaining compliance with global regulations.

Future Implications of Serialization in Blister Packaging for Global Traceability

The evolution of serialization in blister packaging points toward integrated system architectures built on ANSI/ISA-95 standards. These standards create a unified framework for:

- Enterprise Resource Planning (ERP) systems

- Manufacturing Execution Systems (MES)

- Device-level controls

- Regulatory reporting interfaces

The implementation of ANSI/ISA-95 standards enables seamless data flow across different levels of the packaging operation:

- Level 0-1: Physical processes and sensing

- Level 2: Monitoring and supervision

- Level 3: Manufacturing operations

- Level 4: Business planning and logistics

Advanced serialization systems are incorporating artificial intelligence and machine learning capabilities to:

- Predict maintenance needs

- Optimize production schedules

- Detect potential quality issues

- Enhance track-and-trace accuracy

The integration of blockchain technology with ANSI/ISA-95 compliant systems adds an extra layer of security and transparency. This combination creates an immutable record of product movement through the supply chain, strengthening authentication processes and reducing counterfeit risks.

Smart packaging technologies, combined with serialization data, enable real-time monitoring of:

- Environmental conditions

- Temperature variations

- Handling procedures

- Chain of custody verification

These technological advancements drive the pharmaceutical industry toward complete supply chain visibility and enhanced patient safety through robust traceability systems.

Conclusion

Serialization in blister packaging is essential for modern pharmaceutical manufacturing. This advanced tracking system provides:

- Improved patient safety through complete product traceability

- Strong protection against counterfeiting

- Efficient management of product recalls

- Compliance with regulations in global markets

By incorporating serialization technology, pharmaceutical packaging evolves from being just a protective solution to becoming an intelligent system that ensures product integrity throughout the entire supply chain.

Looking to improve your pharmaceutical packaging operations? Check out our detailed guide on Blister Packaging to learn about industry best practices, innovative solutions, and expert insights tailored to your specific packaging requirements. Together, let's create a more secure and traceable pharmaceutical supply chain.

FAQs

1. What is serialization in blister packaging and why is it important for global traceability?

Serialization in blister packaging involves assigning unique serial numbers to individual pharmaceutical units, enabling precise product tracking and tracing throughout the supply chain. This practice is crucial for achieving global traceability, ensuring regulatory compliance, and enhancing supply chain security within the pharmaceutical industry.

2. How do aggregation techniques complement serialization in blister packaging?

Aggregation links serialized individual units hierarchically to larger packaging levels, such as cartons or pallets. This hierarchical linking facilitates end-to-end traceability by allowing stakeholders to track products from manufacturing to the end user efficiently, thereby strengthening supply chain transparency and integrity.

3. What hardware and software systems are essential for effective serialization on blister packaging lines?

Effective serialization solutions require specialized hardware including industrial PCs, cameras, and touch screen displays, alongside robust software systems designed to manage serial number assignment, data capture, and integration with enterprise resource planning (ERP) systems. These components work together to ensure accurate serialization and aggregation processes on blister packaging lines.

4. What design considerations should be made when implementing serialization capabilities in blister packaging lines?

Designing blister packaging lines with serialization capabilities involves accommodating various blister sizes and materials such as PVC, PVDC, and aluminum. The packaging process must be optimized to handle these materials efficiently while integrating serialization technology seamlessly to maintain product integrity and traceability.

5. How does serialization enhance regulatory compliance and supply chain security in pharmaceutical blister packaging?

Serialization ensures that each pharmaceutical unit can be uniquely identified and tracked, which helps meet stringent regulatory requirements globally. It also protects against counterfeiting and diversion by enabling verification of authenticity at multiple points in the supply chain, thereby enhancing overall supply chain security and brand protection.

What are the future implications of adopting serialization standards like ANSI/ISA-95 in blister packaging?

Adopting standards such as ANSI/ISA-95 for system architecture in serialization promotes interoperability, scalability, and efficiency across manufacturing operations. This standardization supports advanced data integration and real-time traceability, positioning pharmaceutical companies to better meet evolving regulatory demands and improve global supply chain transparency.