Key Takeaways

- Pharma checkweighers are mission-critical tools for ensuring dosage accuracy, GMP compliance, and regulatory audit readiness.

- Designed for milligram-level precision, these machines verify every unit on the production line—automatically rejecting under- or overfilled products.

- Leading systems support 21 CFR Part 11 and EU Annex 11 compliance with built-in audit trails, user authentication, and secure electronic records.

- There are multiple types:

- In-line checkweighers for high-speed bottling and blister lines

- Capsule checkweighers for ultra-precision in potent drug manufacturing

- Combination units for integrated weight, metal, and label inspection

- Laboratory/static units for batch sampling and R&D

- Checkweighers are evolving with IoT, AI, and predictive maintenance, turning them into smart quality control systems aligned with Pharma 4.0 goals.

- Choosing the right system requires a balance of accuracy, speed, compliance features, integration capabilities, and total cost of ownership.

- Vendors like Mettler-Toledo, Wipotec-OCS, Anritsu, Ishida, and Thermo Fisher lead the market with validated, pharma-grade machines.

- Qualification (IQ/OQ/PQ), ongoing calibration, and preventive maintenance are non-negotiable for maintaining regulatory compliance.

- Modern checkweighers are no longer just weight inspectors—they are trusted data engines that safeguard product integrity and patient trust.

Introduction

In the high-stakes world of pharmaceutical manufacturing, there's no room for "almost accurate." A tiny discrepancy in weight—a single missing tablet, a slightly underfilled vial—can trigger a chain reaction: failed audits, product recalls, regulatory warnings, and worst of all, risk to patient safety.

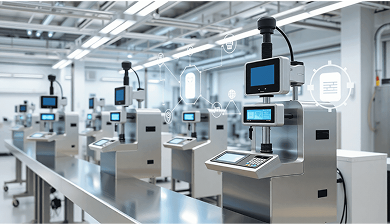

But on every modern production line, there's an unsung hero working quietly behind the scenes—the pharma checkweigher machine.

You won't hear its voice. It doesn't wear a lab coat. But it inspects every single unit at lightning speed, ensuring that each dose is complete, compliant, and consistent. It's not just a machine—it's a frontline guardian of GMP compliance, product integrity, and brand trust.

And in today's regulatory environment—where data integrity, automation, and traceability are no longer optional—checkweighers are more than quality tools. They are regulatory enablers.

This guide is your complete reference to understanding pharmaceutical checkweigher machines:

- What they are and how they work

- Why they're mission-critical for modern pharma plants

- Which types and technologies suit your operation

- How global brands like Mettler-Toledo, Anritsu, and Wipotec-OCS are shaping the future of pharma checkweighing

- And what to look for when choosing a machine that will meet both today's and tomorrow's regulatory demands

Because in pharma, getting the weight right isn't just about precision—it's about patient safety, regulatory trust, and operational excellence.

Let's begin.

I. What Is a Pharma Checkweigher Machine?

To maintain this level of precision, pharmaceutical manufacturers rely on highly specialized equipment—pharma checkweigher machines.

These are automated systems designed to verify the weight of every single product on the production line—at speed, without interrupting the process. Whether it's a bottle of tablets, a blister strip, or a capsule pack, the checkweigher ensures it matches the specified weight with milligram-level accuracy.

If it doesn't, the machine automatically removes the item from the line—without human intervention.

Unlike standard industrial checkweighers, those built for pharmaceutical use are tailored for regulatory compliance, hygiene, and traceability. The difference lies in the details:

- 🔬 High-precision load cells detect even minor deviations

- 🧼 GMP-grade stainless-steel construction supports easy cleaning and contamination control

- 🔐 Data integrity features—like audit trails, secure user access, and electronic record-keeping—enable compliance with 21 CFR Part 11 and EU Annex 11

- 🔗 Seamless integration with metal detectors, vision systems, and serialization modules makes it part of a broader quality ecosystem

At its core, a pharmaceutical checkweigher system plays a dual role:

It safeguards product quality and enables regulatory assurance—with every unit, every time.

As we go further, we'll explore why this machine isn't just an accessory—it's a strategic investment for pharma operations that prioritize quality, compliance, and customer trust.

II. Why Pharma Companies Need Checkweighers

In pharmaceutical manufacturing, precision isn't just a best practice—it's a regulatory obligation. And when every unit must meet exact dosage and packaging standards, relying on manual sampling or random inspections simply isn't enough.

That's why pharma checkweighers are no longer optional—they are essential.

Here's why they matter:

🛡️ 1. Regulatory Compliance

Global regulators like the FDA, EMA, and CDSCO expect documented proof that every product leaving your facility meets its intended specification. Checkweighers provide 100% in-line inspection, backed by audit trails and secure records that support:

- ✅ 21 CFR Part 11

- ✅ EU Annex 11 & 15

- ✅ GMP Clause 211.68 (automatic equipment)

With built-in calibration checks, rejection logs, and data security, they help manufacturers stay inspection-ready at all times.

🎯 2. Dosage Accuracy = Patient Safety

A missing tablet in a blister pack isn't just a packaging issue—it's a risk to patient care.

Pharma checkweighers can detect discrepancies in milligrams, preventing sub-potent or overdosed units from reaching patients. For oncology drugs, hormones, and low-dose therapies, this level of accuracy is critical.

💸 3. Reduction of Overfill and Waste

Overfilling might seem harmless, but across millions of units, even a few extra milligrams per dose can add up to lakhs of rupees in wasted API—especially in high-value formulations.

Checkweighers help manufacturers identify drift in filling equipment early, enabling corrective action and cost control without compromising quality.

🧾 4. Traceability and Electronic Documentation

Modern systems don't just weigh—they record.

Each unit's weight, timestamp, and operator activity can be logged and stored, supporting batch release, root cause investigations, and digital validation processes. These records can be exported, encrypted, and linked with serialization and MES systems for end-to-end traceability.

⚙️ 5. Seamless Automation and Operational Efficiency

With automated rejection, filler feedback loops, and real-time alerts, checkweighers minimize human error and reduce dependency on manual QA checks. This enables faster line speeds, better throughput, and streamlined quality control processes.

In short, checkweighers are not just weighing machines—they are an essential part of the pharmaceutical production fabric, connecting quality control with compliance, efficiency, and cost-saving goals.

III. Types of Pharma Checkweigher Machines

Not all pharmaceutical products are created—or packaged—the same. A blister pack of tablets, a bottle of capsules, a pouch of powder, or a prefilled syringe all demand different weighing strategies.

That's why pharma checkweigher machines come in specialized types, each engineered for a specific purpose. Choosing the right one isn't just about speed—it's about compliance, dosage integrity, and operational fit.

Let's break down the major types trusted by pharmaceutical manufacturers worldwide:

⚙️ 1. In-Line (Dynamic) Checkweighers

Use Case: Bottles, cartons, blisters, pouches

These are the most widely used in pharma packaging lines. In-line checkweighers weigh products in motion, without stopping the flow. With precision load cells and real-time data feedback, they inspect hundreds of units per minute—automatically rejecting any that fall outside the acceptable weight range.

- ✔️ Ideal for high-speed lines

- ✔️ Integrated with reject systems and conveyor belts

- ✔️ Accuracy up to ±10 mg (model dependent)

📌 Example: Mettler-Toledo C35 Pharma, Wipotec HC-A

✅ Why it matters: It ensures 100% inspection at production scale—essential for batch release and GMP compliance.

💊 2. Capsule Checkweighers (High-Precision)

Use Case: Individual capsules (including high-potency drugs)

Designed for one job: weighing capsules with ultra-high accuracy. These machines can weigh up to 120,000 capsules/hour, with accuracy as tight as ±0.5 mg. They're built to detect partially filled, empty, or overfilled capsules—especially important in oncology, hormonal, and controlled substances.

- ✔️ Multi-lane design for high throughput

- ✔️ Inclined chutes and anti-vibration structure

- ✔️ Integrated with batch record-keeping and audit trails

📌 Example: Anritsu KWS Capsule Checker

✅ Why it matters: When dosage accuracy could impact patient survival or regulatory approval, precision is everything.

Capsule Checkweighers: Precision Engineering for Oncology and Potent Drugs

Read more🧪 3. Laboratory / Static Checkweighers

Use Case: R&D labs, QC sampling, clinical batches

Unlike their dynamic counterparts, lab checkweighers are used in controlled environments where products are manually placed for weighing. These are ideal for batch sampling, formulation trials, and micro-dose verification during product development.

- ✔️ Extremely sensitive (sub-milligram resolution possible)

- ✔️ Supports documentation and statistical analysis

- ✔️ Portable or benchtop design

📌 Example: Minebea Intec Signum series

✅ Why it matters: They provide scientific assurance before a product ever hits the production line.

🔗 4. Combination Checkweighers

Use Case: Weight + metal detection + vision + serialization

These are hybrid machines that combine checkweighing with other inspections—such as metal detection, X-ray, or vision systems. They save space, simplify line design, and offer a centralized control point for multiple quality checks.

- ✔️ One footprint, multiple inspection functions

- ✔️ Ideal for serialized lines and compact facilities

- ✔️ Reduce validation complexity

📌 Example: Wipotec TQS-HC-A (weighing + serialization)

✅ Why it matters: With rising compliance demands, these systems offer consolidated assurance in one intelligent machine.

➕ Optional Variants & Configurations

- Multi-lane checkweighers for small-format or high-volume lines

- Wet/dry environment variants with IP65/IP69K protection

- Smart feeders or timing screws for fragile or irregular products

- Filler feedback enabled models for closed-loop control

Choosing the right type of checkweigher depends on your product format, speed requirements, compliance goals, and available line space. In the next section, we'll explore how these machines actually work—what happens behind the scenes once your product hits the belt.

IV. Inside the Machine: How a Pharma Checkweigher Works

A pharma checkweigher may look compact on the outside, but inside, it's a highly engineered system designed to measure, assess, and act in milliseconds—all while maintaining line speed and regulatory precision.

Let's break down how it works—step by step.

🧭 Step 1: Product Enters the Weighing Zone

As each product travels along the conveyor, it's guided into position using timing screws, guide rails, or transfer belts. This ensures consistent placement for weighing, especially on high-speed lines where even slight misalignment can affect accuracy.

✅ EEAT Note: Leading brands like Wipotec-OCS and Anritsu use anti-vibration design and isolated weighing platforms to minimize external interference—crucial for pharma-grade accuracy.

⚖️ Step 2: Weight Is Captured via Load Cell Technology

At the heart of every checkweigher is a load cell—a high-precision sensor that converts force (i.e., product weight) into an electrical signal.

Most pharmaceutical checkweighers use:

- Electromagnetic Force Restoration (EMFR) load cells for ultra-high sensitivity

- Strain gauge sensors for durable, fast-response systems

These sensors measure weight down to ±0.5 mg in some capsule checkweighers, ensuring even a single missing tablet doesn't go unnoticed.

✅ EEAT Insight: Brands like Mettler-Toledo and Anritsu openly publish calibration tolerances and measurement uncertainty—signs of trust and traceability.

🧠 Step 3: Software Compares Measured Weight to Specifications

Once the weight is recorded, it's instantly compared to the product's predefined acceptable range—often pulled from the MES or batch record system.

Modern pharma checkweighers use:

- 📊 Statistical Process Control (SPC) to monitor trends

- 🔁 Real-time feedback loops to fillers for auto-correction

- 🔒 Secure logs of every pass/fail with time, batch, and operator info

This is where compliance meets control—because every decision the machine makes is logged, traceable, and audit-ready.

❌ Step 4: Non-Conforming Product Is Rejected Automatically

If a product falls outside the allowed weight range, the system triggers an automated reject mechanism—such as:

- Air jets

- Pushers

- Drop flaps

- Diverters with lockable bins (for compliance)

Some systems even tag rejected products with barcode scanners, adding layered traceability for investigations or recalls.

✅ Compliance Check: Under GMP, all rejected items must be accounted for and investigated—something modern checkweighers simplify with digital rejection logs and sensor-verified ejection.

🔄 Step 5: Data Is Logged, Synced, and Ready for Audit

The final, and perhaps most important, function is data management.

All weighing events—successful or rejected—are logged with:

- Timestamps

- Batch numbers

- Operator IDs (via secure logins)

- Reason codes (e.g., underweight, overfill)

Top-tier checkweighers support:

- 21 CFR Part 11 compliance

- EU Annex 11 for computerized systems

- Audit trails, electronic signatures, and encrypted data export

✅ EEAT Anchor: Systems from companies like Mettler-Toledo and Wipotec support full integration with ERP/MES systems, creating an uninterrupted chain of traceability from production to release.

🧰 Behind the Simplicity: Precision Engineering

From conveyors to sensors, every part of a pharma checkweigher is designed for:

- 🔧 Tool-less maintenance

- 🧼 Hygienic washdown (IP65–IP69K)

- 📉 Vibration damping and zero drift

- 📡 Network compatibility (OPC-UA, Ethernet/IP)

It's not just a machine. It's an intelligent quality control node, designed to make decisions faster, more consistently, and more reliably than any human operator ever could.

V. Top Pharma Checkweigher Brands & Models

Choosing a checkweigher isn't just about specs—it's about trust. In the pharmaceutical industry, where regulatory scrutiny is high and margins for error are razor-thin, manufacturers rely on proven global brands that deliver both performance and compliance.

Below are some of the most respected names in pharmaceutical checkweighing, along with their flagship models and what sets them apart.

Mettler-Toledo (Hi-Speed / Garvens)

Model to Know: C35 AdvancedLine Pharma

Country: Switzerland / Global

Known For: Data integrity, audit-readiness, robust support

- ✔️ In-line dynamic weighing up to 600 ppm

- ✔️ Accuracy: ±10 mg (model-specific)

- ✔️ Built-in 21 CFR Part 11 compliance

- ✔️ Integrated reject bin sensors & product tracking

- ✔️ Compatible with ProdX software for centralized quality monitoring

🔍 Why pharma trusts it: Mettler-Toledo's systems are GMP-ready out of the box and designed for seamless qualification, calibration, and MES integration.

Wipotec-OCS

Model to Know: HC-A-Pharma / HC-A-MI

Country: Germany

Known For: Milligram-level precision, modular customization

- ✔️ EMFR load cells for ultra-high sensitivity

- ✔️ Accuracy: ±1–5 mg (HC-A-MI)

- ✔️ Multi-track configurations available

- ✔️ Ready for serialization & vision integration (TQS series)

- ✔️ Hygienic design with open, vibration-stable frames

🔍 Why pharma trusts it: Wipotec checkweighers offer exceptional flexibility for high-speed and high-precision applications, especially in EU-regulated markets.

Anritsu Industrial Solutions

Model to Know: KWS Capsule Checker

Country: Japan

Known For: Precision capsule weighing, high throughput

- ✔️ Throughput: Up to 120,000 capsules/hour

- ✔️ Accuracy: ±0.5 mg

- ✔️ Multi-lane capsule handling

- ✔️ 21 CFR Part 11 software with audit trail and user access control

- ✔️ Optimized for oncology and high-potency drug filling lines

🔍 Why pharma trusts it: Anritsu leads the capsule checkweigher category. Their systems are purpose-built for pharma and backed by years of validation expertise.

Top Pharma Checkweigher Brands Compared: Mettler vs Wipotec vs Anritsu

Read moreIshida

Model to Know: DACS-GN Series

Country: Japan

Known For: Reliable in-line weighing with strong accuracy-to-cost ratio

- ✔️ Multi-range weighing up to 300 ppm

- ✔️ Accuracy: ±0.2–2 g (based on range)

- ✔️ Digital load cells with fast response

- ✔️ Available in IP65–IP69K configurations

- ✔️ Optional combo with CEIA metal detection

🔍 Why pharma trusts it: Ishida is often selected by mid- to large-scale facilities needing speed and reliability with solid compliance.

Thermo Fisher Scientific

Model to Know: Global Versa GP

Country: USA

Known For: Rugged design, integrated inspection platforms

- ✔️ Accuracy: ±0.3–0.5 g depending on product range

- ✔️ Integrated combo units available (metal detection + weighing)

- ✔️ Designed for washdown and pharma/biotech environments

- ✔️ Simple validation tools for fast qualification

- ✔️ Good choice for nutraceuticals and OTC segments

🔍 Why pharma trusts it: Thermo Fisher combines durability with integration flexibility, especially in hybrid product lines or regional facilities.

📊 Comparison Snapshot

🧠 What to Consider When Choosing a Brand

- Precision vs. Throughput: Capsule lines need higher accuracy; bottle lines may prioritize speed

- Compliance Requirements: Look for brands with built-in 21 CFR Part 11 or Annex 11 features

- Integration Compatibility: Choose systems that work with your MES, ERP, or serialization tools

- Local Support & Calibration Services: Essential for ongoing qualification and preventive maintenance

- Total Cost of Ownership (TCO): Beyond price—consider software, spare parts, service, and operator training

These are the machines trusted by global pharma leaders for a reason: they deliver proven performance under regulatory pressure. And when your batch release, audit trail, and brand reputation are on the line—trust matters.

VI. Key Buying Considerations for Procurement & QA Teams

Selecting a pharma checkweigher isn't a one-size-fits-all decision. For QA leaders, production heads, and procurement teams, it's a strategic investment—one that must align with compliance needs, operational goals, and long-term cost efficiency.

Here are the most critical factors to evaluate before you buy:

🧪 1. Accuracy Requirements Based on Product Type

Start by defining your accuracy threshold. A capsule line for high-potency drugs may demand ±0.5 mg precision, while a carton line might tolerate ±100 mg. Over-specifying increases cost; under-specifying risks non-compliance.

- Capsules or prefilled syringes: Look for high-precision, multi-lane machines

- Blister packs or bottles: Focus on dynamic in-line models with milligram accuracy

- Powders or small sachets: Consider sensitivity to environmental factors (vibration, static)

✅ EEAT Tip: Ask for test certificates and calibration traceability to validate accuracy claims.

🔐 2. Regulatory Compliance Built-In

The checkweigher must support:

- 21 CFR Part 11: Secure login, audit trails, electronic signatures

- EU Annex 11: Computerized systems compliance

- GMP Equipment Guidelines: Materials, cleanability, and operational documentation

Also ask:

- Does the machine provide validation documentation (DQ/IQ/OQ/PQ)?

- Is there an audit log for rejected items?

- Are passwords and access levels configurable?

✅ Pro Insight: Don't retrofit compliance—choose models designed with validation-readiness from day one.

⚙️ 3. Integration with Your Line and Systems

Modern pharma checkweighers should fit seamlessly into your existing packaging line and IT infrastructure.

- MES/ERP Compatibility: OPC-UA, Ethernet/IP, or custom APIs

- Track & Trace Systems: Serialization, vision inspection, barcode readers

- Reject handling logic: Is it integrated with alarms or batch hold logic?

✅ Checklist: Always involve your IT/automation team in the early evaluation phase.

💼 4. Ease of Use and Operator Training

No matter how accurate, a checkweigher is only as good as its usability. Prioritize:

- Touchscreen HMI with user-friendly interface

- Quick recipe changeovers

- Guided calibration and test routines

- Built-in tutorials or error diagnosis

✅ Procurement Note: Ensure training is included in the purchase or AMC package—especially if you're scaling operations.

🧼 5. Hygienic and Maintenance-Friendly Design

Pharmaceutical environments require fast, tool-less cleaning and maintenance.

- IP65/IP69K protection for washdown

- Sloped surfaces and removable belts

- Stainless steel, non-reactive materials

- Built-in self-check or calibration prompts

✅ GMP Alignment: Equipment design should reduce the risk of cross-contamination and be easy to sanitize between batches.

💰 6. Total Cost of Ownership (TCO)

Don't just consider the purchase price—evaluate the full lifecycle cost:

- Downtime impact if service is delayed

- Availability of local support and spare parts

- Cost of annual calibration and software updates

- Integration costs with upstream/downstream systems

✅ Decision Metric: Choose partners—not just vendors—who offer long-term support, validation assistance, and process consulting.

🧾 Bonus: Procurement RFP Questions

Before finalizing a vendor, ensure your RFP includes:

- What is the smallest weight deviation the system can detect?

- What's the average uptime and MTBF (Mean Time Between Failures)?

- Is it validated in another regulated pharma facility?

- Can it be demonstrated on your product samples?

- Does the software meet FDA/EMA data integrity standards?

The goal is simple: find a checkweigher that fits your operation today—and is flexible enough to grow with your process tomorrow.

VII. Is Your Checkweigher Pharma-Ready? [10-Point Compliance Checklist]

Before a checkweigher can be trusted to manage quality control in a pharmaceutical environment, it must prove it's more than just technically sound—it must be compliance-ready, cleanroom-compatible, and designed for data integrity.

Use this 10-point checklist to evaluate whether a checkweigher truly meets pharmaceutical standards.

✅ 1. GMP-Compliant Material Construction

- Is the frame and contact surface made from stainless steel (AISI 304 or 316)?

- Are all materials non-corrosive and non-reactive?

✅ Why it matters: Prevents contamination and supports cleaning validation.

✅ 2. Tool-Less Cleaning and Maintenance

- Can belts, sensors, and reject mechanisms be cleaned without tools?

- Are surfaces sloped or open-frame to prevent particle accumulation?

✅ Why it matters: Ensures rapid turnaround between batches and hygiene control.

✅ 3. Calibrated, Validated Weighing System

- Is the load cell calibrated with traceable standards?

- Does the vendor provide IQ/OQ/PQ documentation?

✅ Why it matters: Supports regulatory audits and continuous accuracy monitoring.

✅ 4. 21 CFR Part 11 & EU Annex 11 Ready

- Does it support secure logins, user-level access, audit trails, and electronic signatures?

- Are records tamper-evident and exportable?

✅ Why it matters: Meets data integrity expectations for global compliance.

✅ 5. Integrated Reject Mechanism with Bin Locking

- Is there a controlled, sensor-verified reject system?

- Is the reject bin lockable with restricted access?

✅ Why it matters: Supports traceability and prevents unauthorized product retrieval.

✅ 6. Product Recipe & Batch Management

- Can different product configurations be stored and recalled?

- Does it log batch-specific weight and rejection data?

✅ Why it matters: Speeds up changeovers and maintains batch-level compliance.

✅ 7. Environmental Stability Features

- Are vibration dampers or anti-static systems present?

- Is the checkweigher enclosed or shielded for airflow-sensitive lines?

✅ Why it matters: Minimizes weight deviation due to environmental noise.

✅ 8. Compatible with MES / Serialization Systems

- Can the checkweigher integrate with ERP, MES, or serialization lines?

- Are communication protocols like OPC-UA or Ethernet/IP supported?

✅ Why it matters: Future-proofs the system for Pharma 4.0 and traceability.

✅ 9. Self-Test, Zero Tracking & Auto-Calibration

- Are there automated test routines or built-in weights?

- Can zero drift be compensated during runs?

✅ Why it matters: Reduces manual errors and flags calibration issues early.

✅ 10. Vendor Support, Documentation & Serviceability

- Does the vendor offer local support, training, and annual maintenance contracts?

- Are spare parts readily available?

✅ Why it matters: Sustains long-term performance and ensures compliance continuity.

🧠 Pro Tip for QA & Procurement Teams:

Use this checklist during factory acceptance tests (FAT), site qualification, or RFP evaluations to ensure you're investing in a machine that will pass audits—not just pass cartons.

Next, we'll dive deeper into what compliance really means—focusing on regulatory expectations, qualification processes, and audit-readiness.

VIII. Compliance & Qualification: Meeting FDA and EU GMP Standards

In the pharmaceutical industry, even the most advanced checkweigher is only as valuable as its regulatory acceptability. A machine that isn't validated, traceable, or aligned with data integrity principles won't just fail an audit—it could compromise your entire batch release process.

That's why every pharma checkweigher must stand up to two fundamental questions:

✅ Is it built to meet global GMP requirements?

✅ Can it withstand regulatory scrutiny with documentation and controls?

Let's break this down.

📘 1. GMP Guidelines: What They Expect from Checkweighers

Both FDA (21 CFR 210, 211) and EU GMP define clear expectations for equipment used in pharmaceutical manufacturing:

- Materials of Construction: Must be non-reactive, non-additive, and easily cleanable (typically stainless steel)

- Design for Cleanability: No dead zones, exposed fasteners, or crevices that can harbor contaminants

- Preventive Maintenance & Calibration: Regular intervals with traceable standards

- Cross-contamination Control: Rejection bins and product flow must be isolated

- Process Validation: The system must be qualified—Installation (IQ), Operational (OQ), and Performance Qualification (PQ)

🧠 EEAT Tip: Global checkweigher leaders like Mettler-Toledo, Wipotec, and Anritsu offer IQ/OQ/PQ packages and GAMP 5-based documentation to reduce the burden on your QA teams.

🔐 2. Data Integrity: 21 CFR Part 11 & EU Annex 11

When a checkweigher logs product weights, rejections, and calibration data, it becomes part of your regulated electronic record system. Regulators expect this data to be:

- Attributable (who performed the action?)

- Legible

- Contemporaneous (timestamped)

- Original

- Accurate

This is the ALCOA+ framework.

To meet it, your checkweigher must offer:

- 🔒 Role-based access control

- 📝 Audit trails that track every change and action

- 🔑 Electronic signatures and login authentication

- 💾 Secure, encrypted data storage and export

- 📤 Non-editable reports for compliance inspections

✅ Part 11 Compliant Software is not optional. It's a requirement if the data will be used for batch release or electronic records.

🛠️ 3. Qualification: IQ, OQ, PQ Process

Before going live in production, the checkweigher must undergo formal qualification:

- IQ (Installation Qualification): Verifies that the machine and its environment are correctly set up. Includes utility checks, software installation, etc.

- OQ (Operational Qualification): Tests functionality—does the system weigh, reject, and log data as intended? Includes challenge tests and calibration verification.

- PQ (Performance Qualification): Assesses performance under actual operating conditions. Typically done on a full production batch with real product.

🧾 Vendor Tip: Choose vendors who can assist with these documents—or better, co-execute them with your QA team during commissioning.

🔄 4. Ongoing Compliance: Maintenance, Calibration & Documentation

After qualification, the work doesn't stop. Regulatory agencies expect:

- 📆 Scheduled calibration intervals (with test weight traceability)

- 🛠️ Preventive maintenance logs

- 📋 Change control procedures if hardware/software is updated

- 📈 Re-validation or requalification after major changes or relocations

Most GMP-compliant pharma facilities also conduct:

- Routine challenge tests during each batch to confirm rejection performance

- Audit trail reviews during QA batch record checks

- Integration of checkweigher data with eBMR (electronic batch manufacturing records)

✅ Best Practice: Treat your checkweigher like a critical control point—not just a machine. Document everything.

🧾 Summary: The Compliance Litmus Test

A pharma-ready checkweigher must meet three critical pillars:

- GMP Equipment: Cleanability, material traceability, hygienic design

- Data Integrity: Audit trails, Part 11 compliance, role-based access

- Qualification: IQ/OQ/PQ protocols, calibration logs, vendor documentation

Pharma checkweighers aren't just equipment—they're regulatory risk mitigators. The stronger your compliance foundation, the more confidently you can scale production, face audits, and release life-saving products.

Understanding IQ/OQ/PQ for Pharma Checkweighers: Qualification Without the Stress

Read moreIX. Emerging Trends & Innovations in Pharma Checkweighing

The pharmaceutical industry is rapidly transitioning from compliance-driven automation to intelligence-driven manufacturing. As part of this shift, checkweighers are evolving beyond precision scales into smart, connected quality control systems—becoming integral nodes in the digital pharmaceutical ecosystem.

Let's explore the technological and strategic trends reshaping the role of pharma checkweighers in 2025 and beyond.

📡 1. IoT-Enabled Checkweighers for Real-Time Monitoring

Modern checkweighers are no longer standalone devices—they're becoming real-time data hubs. IoT connectivity enables:

- 📊 Live monitoring of weight trends across shifts or batches

- 🔁 Automated feedback loops to filling systems to correct drifts instantly

- 🔗 Integration with MES/ERP systems for continuous batch data mapping

- 🧠 Centralized dashboards for remote production and QA visibility

✅ Example: Wipotec's checkweighers with OPC-UA support can push live performance metrics to control rooms, enabling predictive adjustments without operator intervention.

🧠 Why it matters: In Pharma 4.0 environments, data is the new audit trail. IoT turns your checkweigher into a strategic compliance assurance tool—not just a machine.

How IoT and AI Are Transforming Pharma Checkweighers into Smart QA Systems

Read more🤖 2. AI-Powered Analytics and Pattern Detection

Artificial Intelligence is enabling checkweighers to move from rule-based rejection to intelligent decision-making. Key applications include:

- 🧠 Anomaly detection based on learned production patterns

- ⚙️ Auto-adjusting tolerance bands to minimize false rejects

- 🔄 Predictive analytics that forecast filler drifts before they occur

- 📈 Performance benchmarking across shifts, machines, and sites

✅ Example: Some checkweighers now use AI to adapt weighing sensitivity during hot/cold shifts or high-vibration periods—where standard logic might fail.

🧠 Why it matters: AI reduces human dependency, drives consistency, and enables self-optimizing quality control, aligning with FDA's evolving focus on continuous process verification (CPV).

🔮 3. Predictive Maintenance and Self-Diagnostics

Unplanned downtime can delay entire batches. Checkweighers equipped with self-monitoring sensors and predictive logic can:

- 🧰 Track motor load, vibration, and temperature to predict wear

- 🔧 Trigger maintenance alerts before critical thresholds are crossed

- 📅 Integrate into CMMS (Computerized Maintenance Management Systems)

✅ Example: Mettler-Toledo's predictive maintenance modules notify operators about belt tension issues or calibration drift—before performance deteriorates.

🧠 Why it matters: This reduces emergency interventions and aligns with GMP's expectation of preventive maintenance and continuous performance assurance.

🧬 4. Integration with Serialization & Vision Inspection

With serialization and data traceability becoming mandatory across regulated markets, pharma manufacturers are adopting multi-layer inspection systems. Checkweighers are now bundled with:

- 📸 Vision systems (for label, barcode, and 2D code verification)

- 🧮 Serialization modules (for unique pack ID tracking)

- 🤝 Track-and-trace logic that links each product's weight to its serial ID

✅ Example: Wipotec's TQS-HC-A integrates checkweighing, serialization, and tamper-evident labeling—all in a single validated unit.

🧠 Why it matters: This ensures that not just the weight—but also the identity, label, and data integrity of each unit is verified before release.

📲 5. Remote Validation, AR Support & Digital Twin Integration

COVID-19 catalyzed a shift toward remote machine validation and support, which is now being further developed using:

- 🌐 Cloud-based validation portals for IQ/OQ/PQ traceability

- 🥽 AR-assisted troubleshooting and training for technicians

- 🧿 Digital twin models for simulating checkweigher performance in virtual environments

✅ Example: Leading vendors are now offering remote FAT (Factory Acceptance Testing) with real-time video, digital calibration logs, and traceable validation reports.

🧠 Why it matters: It reduces setup time, lowers travel/logistics overhead, and enhances regulatory transparency during qualification.

🧭 6. Enhanced HMI & Operator Experience

As pharmaceutical facilities adopt more automation, equipment interfaces are becoming more intuitive and operator-friendly:

- 📱 Large touchscreens with guided workflows

- 🌍 Multi-language support for global teams

- 🎓 Training modules and alert explanations built into the HMI

- 🧪 "Smart Start" calibration wizards and product auto-learning features

✅ Example: Ishida's new generation checkweighers offer pictogram-based menus and recipe recall for faster batch changeovers.

🧠 Why it matters: Minimizing training time and reducing operator errors is essential in GMP-regulated facilities, especially those managing multiple SKUs or shifts.

🌱 7. Sustainability in Equipment Design

With ESG (Environmental, Social, Governance) becoming boardroom priorities, checkweighers are also being evaluated for:

- ⚡ Lower energy consumption

- 🔄 Use of recyclable or eco-certified components

- 🧩 Modular builds for easy upgrades (vs. full replacement)

- 💻 Remote diagnostics to reduce travel-based carbon footprint

✅ Example: Some Wipotec systems are now designed with energy-efficient motors and offer remote service contracts as a carbon-reduction initiative.

🧠 Why it matters: Sustainability is no longer optional—it's increasingly embedded in vendor qualification and CAPEX approval processes.

📌 The Future of Checkweighing in Pharma

From milligram detection to machine intelligence, pharma checkweighers are evolving into smart, self-aware systems that do more than just weigh. They now ensure traceability, compliance, efficiency, and sustainability—in real time.

The innovations discussed aren't just technical upgrades—they're strategic enablers that help pharma companies:

- Accelerate batch release

- Improve regulatory confidence

- Drive cost control

- Support data-driven operations

- Prepare for global serialization and CPV mandates

X. FAQs – Pharma Checkweighers Simplified

1. What is the primary function of a pharma checkweigher?

A pharma checkweigher verifies the weight of every product—such as a blister pack, bottle, or capsule—on the production line. If a product falls outside the acceptable range, it's automatically rejected. It ensures dosage accuracy, regulatory compliance, and batch quality assurance.

2. How accurate are pharmaceutical checkweighers?

Leading pharma checkweighers can detect weight deviations as small as ±0.5 mg, especially in capsule applications. For larger products like cartons or bottles, typical accuracy ranges between ±10–50 mg, depending on the system and speed.

3. What's the difference between a checkweigher and a metal detector?

- A checkweigher measures weight and identifies underfilled or overfilled units.

- A metal detector identifies metallic contamination within a product.

- Many pharma lines use combination systems that include both in a single unit.

4. Is calibration mandatory for pharma checkweighers?

Yes. GMP and regulatory bodies require routine calibration using certified test weights. Calibration must be documented, traceable, and often forms part of daily or per-batch startup routines. Most pharma-grade checkweighers also include auto-zero and test weight verification features.

5. Can checkweighers integrate with MES or serialization systems?

Absolutely. Most modern pharma checkweighers support OPC-UA, Ethernet/IP, and other industrial protocols for real-time data sharing with MES, ERP, or serialization modules—linking each product's weight to its unique digital record.

6. What happens to rejected products?

Rejected products are diverted using automated reject systems (e.g., air jets, pushers) into locked reject bins. Advanced systems log reason codes, timestamps, and photos or video to support batch reconciliation and investigations.

7. Is 21 CFR Part 11 compliance necessary?

Yes—if the checkweigher generates or stores data used in batch release or QA review. The system must support:

- Secure logins and role-based access

- Tamper-evident audit trails

- Electronic signatures

- Non-editable, exportable reports

8. Can a checkweigher detect missing tablets in a sealed blister pack?

Yes. The weight of a fully filled blister is known. Even one missing tablet can result in a detectable deviation—especially with EMFR load cells used in high-precision machines.

9. Do checkweighers work with all dosage forms?

Yes, but with configuration. Different formats (capsules, liquids, powder sachets, prefilled syringes) require:

- Correct conveyor design

- Proper load cell capacity

- Tailored reject mechanisms

- Sometimes, vibration control or static shielding

10. How often should checkweighers undergo preventive maintenance?

Most pharma facilities schedule monthly or quarterly preventive maintenance, along with daily calibration checks. Newer systems also support predictive maintenance, which flags issues before failures occur.