by Mrudula Kulkarni

7 minutes

Active Air vs. Settle Plates vs. Contact Plates: Choosing the Right Environmental Monitoring Method

Compare active air, settle plates, and contact plates to choose the right cleanroom environmental monitoring method.

Walk into a cleanroom, and you’ll notice the silence. Machines hum softly, operators move with precision, and the air itself feels different. That’s not an accident.

In pharmaceutical manufacturing, especially sterile drug production, the air is as critical as the raw materials. Invisible microorganisms can compromise product sterility and, ultimately, patient safety.

This is why environmental monitoring (EM) sits at the heart of regulatory compliance. Regulators like the FDA, EMA, and WHO expect facilities to validate that their controlled environments truly remain controlled. But here’s the challenge: not all EM methods are created equal.

Three of the most widely used tools are active air sampling, settle plates, and contact plates. Standards like USP <1116> cleanroom guidance further highlight how these methods should be balanced within a risk-based monitoring program.

Each has strengths, limitations, and a place in a robust contamination control strategy. Let’s break them down.

Active Air Sampling

What it is:

Active air samplers mechanically pull in a known volume of air and impact it onto a nutrient agar plate. Common devices include slit-to-agar samplers, sieve impactors, and centrifugal samplers.

Strengths:

- Quantitative results: Reports CFU/m³, giving a measurable microbial load.

- Real-time control: Allows targeted monitoring of critical zones (e.g., filling lines, laminar airflow hoods).

- Regulatory preference: EU Annex 1 (2022) specifically emphasizes active monitoring in Grade A and B environments.

Limitations:

- Requires calibrated equipment and regular maintenance.

- Sample volume is finite (usually 1 m³ or less per run).

- Noise and airflow disturbance may interfere with critical operations.

Best used for:

High-risk areas where real-time, quantitative assessment is critical — especially aseptic processing lines.

Settle Plates (Passive Air Monitoring)

What it is:

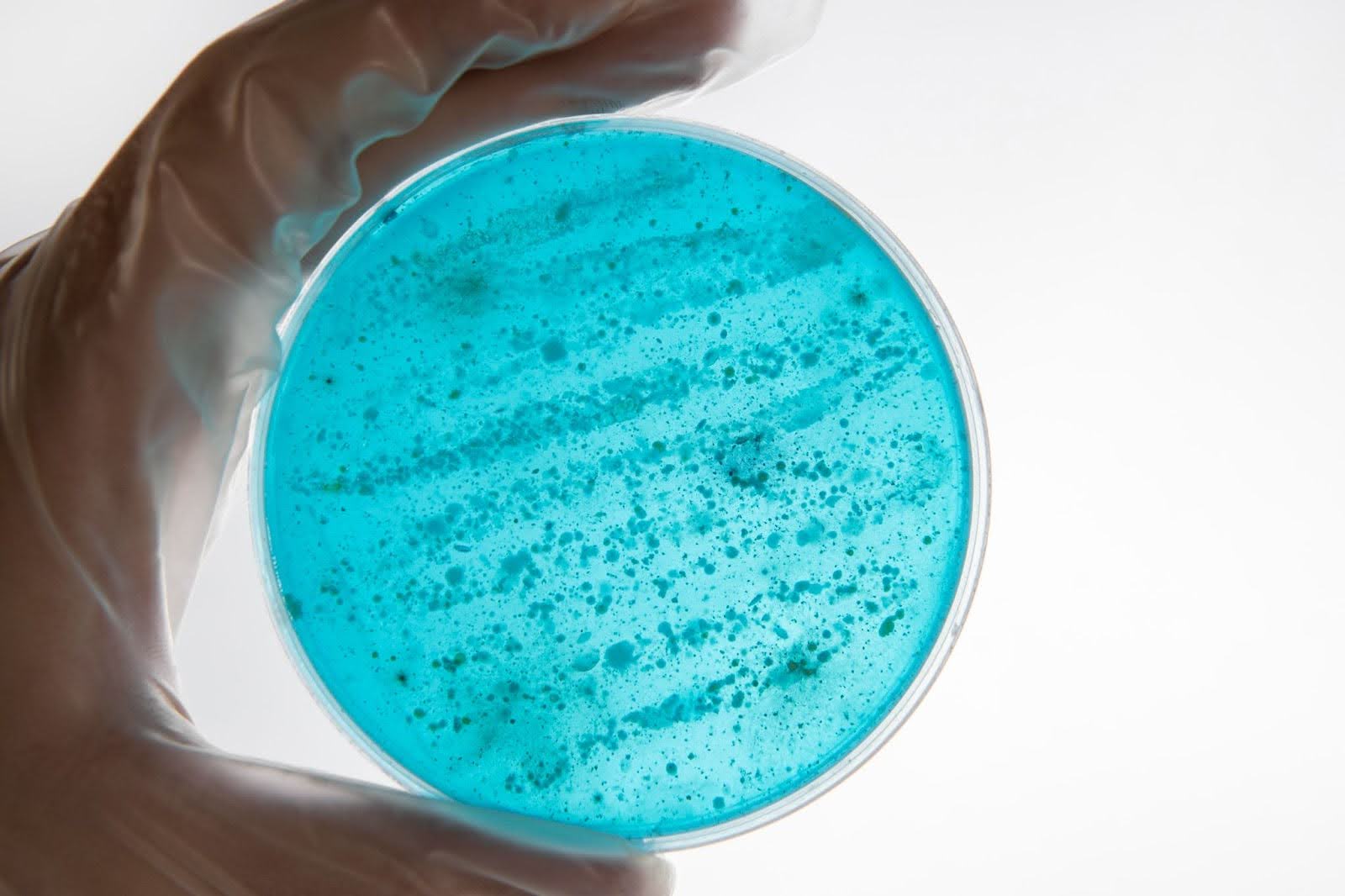

Petri dishes with nutrient agar left open for a defined period (usually 2–4 hours) to capture microorganisms that “settle out” of the air. Following ISO 14644 cleanroom classifications ensures that settle plate data is interpreted within the correct cleanroom grade requirements.

Strengths:

- Simple and inexpensive: No specialized equipment needed.

- Long exposure times capture intermittent contamination events.

- Reflects actual fallout risk onto product-contact surfaces.

Limitations:

- Qualitative, not quantitative: No defined air volume sampled.

- Results heavily depend on air currents, placement, and exposure time.

- Considered supplementary rather than primary by regulators.

Best used for:

Trend analysis, background monitoring, and capturing fallout risk in less critical cleanroom zones. Choosing the right environmental monitoring vendors and software also plays a critical role in ensuring consistency and regulatory confidence.

Contact Plates (Surface Monitoring)

What it is:

Agar-filled plates with a convex surface pressed directly onto equipment, walls, floors, or gloves to detect surface contamination.

Strengths:

- Direct measurement of surface cleanliness.

- Excellent for verifying cleaning and disinfection effectiveness.

- Identifies potential operator-related contamination (e.g., gloves).

Limitations:

- Limited to flat, accessible surfaces (not suitable for irregular shapes).

- Repeated use may damage surfaces or leave residue.

- Requires careful technique to avoid false positives.

Best used for:

Routine monitoring of product-contact surfaces, operator gloves, and critical equipment after cleaning.

Comparing the Three Methods

Regulatory Lens

- EU Annex 1 (2022): Strong emphasis on active air sampling in aseptic zones; settle plates considered supportive, not primary.

- USP <1116>: Highlights the importance of monitoring strategy over reliance on a single method; encourages risk-based combinations.

- WHO TRS 961: Recognizes contact plates as critical for verifying cleaning validation and operator hygiene.

The consensus? No single method is enough. A robust strategy begins with designing an environmental monitoring program that identifies optimal sampling locations and frequency.

Wrapping Up

Active air, settle plates, and contact plates each tell a different part of the cleanroom’s story. Active air gives you hard numbers, settle plates show what’s “falling out” over time, and contact plates prove whether your surfaces and operators are truly clean.

In modern pharma, it’s not about choosing one—it’s about knowing where and when to use each. Together, they provide the 360° visibility you need to protect patients, pass inspections, and build confidence in your contamination control strategy.

The latest Annex 1 environmental monitoring CCS reinforces this layered approach by requiring a documented, holistic contamination control strategy.

FAQs

1. What is environmental monitoring in cleanrooms?

Environmental monitoring (EM) refers to testing the cleanroom environment for microbial and particulate contamination to ensure compliance with regulatory standards and product safety.

2. What is the difference between active air, settle plates, and contact plates?

- Active Air Sampling: Uses devices to draw in a known volume of air and impact microorganisms onto agar.

- Settle Plates: Expose open agar plates for a fixed time to passively capture falling microorganisms.

- Contact Plates: Press agar plates directly onto surfaces to detect contamination.

3. Which method is most reliable for cleanroom air quality monitoring?

Active air sampling is generally considered more reliable, as it quantifies microorganisms per cubic meter of air. However, settle plates and contact plates complement this by detecting viable contamination that air samplers may miss.

4. Do regulators like the FDA and EMA prefer one method over another?

No. Regulatory guidelines (e.g., EU GMP Annex 1, USP <1116>) recommend using a combination of methods to build a comprehensive environmental monitoring program.

5. When should I use settle plates instead of active air samplers?

Settle plates are particularly useful for continuous monitoring during operations when placing active samplers may interfere with workflow.