by Ravindra Warang

7 minutes

PVC-Free, Recyclable, and Compostable Blister Packs: The Future of Green Pharma Packaging

Pharma packaging is going green. Discover how companies are replacing PVC blister packs with sustainable, compliant alternatives.

It started with a single letter.

An environmental NGO published a report that went viral in India’s business circles: “The Pharmaceutical Sector’s Role in India’s Growing PVC Waste Crisis.” The report revealed that over 12 billion blister packs—mostly made with PVC and aluminium—end up in landfills each year. These packs are unrecycled and non-biodegradable, contributing significantly to plastic pollution.

Anjali, the Head of Sustainability at a top Indian pharmaceutical exporter, sat silently as she read the report. Her team had just won the CMO Innovation Award. They’d invested in quality systems, automation, and lean packaging. But one question remained: What about the environmental impact of packaging?

That moment marked the beginning of the company’s transition to sustainable blister packaging. As the pharmaceutical industry grapples with the realities of the PVC waste crisis, Anjali recognized the urgent need for eco-friendly pharma packaging solutions that minimize carbon emissions and promote a circular economy.

She began exploring various blister pack alternatives, including compostable options and innovative materials like r-PET (Recycled Polyethylene Terephthalate) and Aclar. Paper blister packs emerged as viable options to replace traditional PVC while ensuring product safety and integrity. Considering mono-material blister packaging advantages was key to effectively reducing plastic waste.

Why PVC Needs to Be Phased Out

PVC (polyvinyl chloride) has been widely used in pharmaceutical blister packaging due to affordability, clarity, and thermoforming capabilities. However, its environmental drawbacks are significant. PVC contains toxic chemicals such as plasticizers like phthalates, and when incinerated, releases harmful dioxins.

When bonded with aluminum foil—as in typical push-through blister packs—this combination severely limits recyclability. Several countries, especially in the EU, are moving toward banning or taxing PVC under Extended Producer Responsibility (EPR) frameworks.

Regulatory bodies and major pharmacy chains globally demand PVC-free packaging formats to ensure greater recyclability and reduce risks associated with toxic chemicals. Safer alternatives include PVC/PVdC (Polyvinylidene Chloride) or r-PP (Recycled Polypropylene).

Innovative solutions such as PET and EnviroSense® PaperBlister™ Packaging are emerging to minimize environmental impact while ensuring product safety. Finding plastic-free blister pack solutions is increasingly important for companies committed to sustainability. Explore our in-depth blister packaging guide to understand the core principles, material trends, and technology advancements in pharma packaging.

Material Trials: Searching for Sustainable Alternatives to Blister Packs

Pharmaceutical companies are actively exploring sustainable alternatives that meet performance and sustainability criteria. Material trials identify options that ensure safety and efficacy while reducing environmental impact.

PET mono-materials are the most viable replacement for PVC due to recycling compatibility and acceptable barrier properties. PLA-based films and paper-based packs are popular for low-barrier drugs and samples. r-HDPE is also considered for recyclability and compostability.

Factors like SFI™ Forest Management Certification and reduction of dioxins in production processes are gaining importance. Reusable medicine containers present innovative waste-reduction solutions. Discover the top blister packaging machine manufacturers advancing sustainable automation globally.

Understanding cold forming processes ensures regulatory compliance. Compare thermoform vs cold form blister packaging to make informed decisions for moisture-sensitive or light-sensitive formulations. Exploring these materials helps pharma companies align decisions with environmental goals by adopting plastic-free blister packs where possible.

The Vendor Journey: Finding the Right Partner

Switching to sustainable materials requires close collaboration with vendors specializing in sustainable materials. Companies must ensure machinery compatibility while considering barrier requirements, sealing performance, and regulatory compliance.

Some materials pose challenges with sealing integrity, printability, or humidity resistance—especially addressing microplastic pollution concerns. Successful trials often require die-line design modifications or film gauge adjustments. Ensure quality control with our guide on blister leak detection using vacuum decay and dye ingress methods.

Developing sustainable blister packaging using materials like Cold Form Film or PET demands working closely with vendors prioritizing energy-efficient manufacturing. Long-term partnerships support scale-up and stability testing.

Understanding different types of blister packaging production is vital for companies seeking eco-friendly recyclable options. Consider alternatives like paper film or paperboard instead of traditional materials to reduce environmental impact.

What Global Pharma is Doing

The Nordics utilize innovative materials like Paper Film to reduce plastic-based blister pack impact.

- Johnson & Johnson explores bio-based films for pediatric medicines, aiming to replace Aluminium Foil and Polypropylene (PP) with biodegradable alternatives.

- Indian players like Biogreen and Huhtamaki roll out fiber-based blister prototypes for herbal and Ayurveda products aligning with global sustainability initiatives.

Understanding sustainable blister packaging optimizes manufacturing processes towards sustainability goals. For a deeper material-by-material comparison, explore our feature on comparing blister packaging materials for pharma applications. Cold form blister packaging can enhance product protection while reducing environmental impact.

Consider regulatory issues such as plastic laminate separation in recycling when selecting materials like PET mono-materials for better sustainability outcomes.

Companies like Bayer offer sustainable options including refillable medicine bottles supporting green pharma packaging innovation.

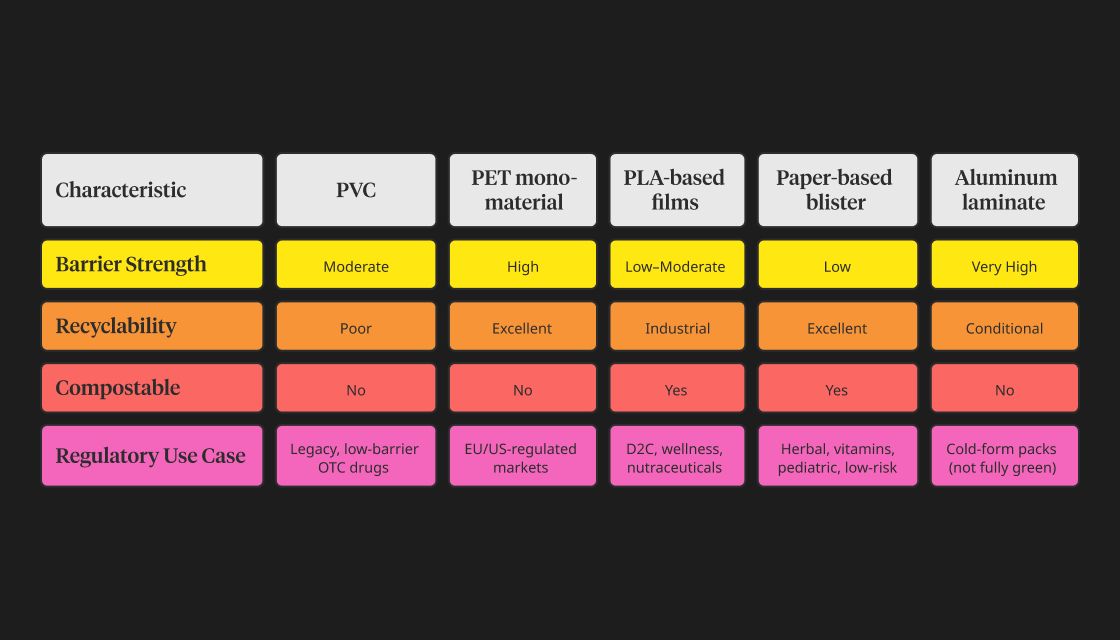

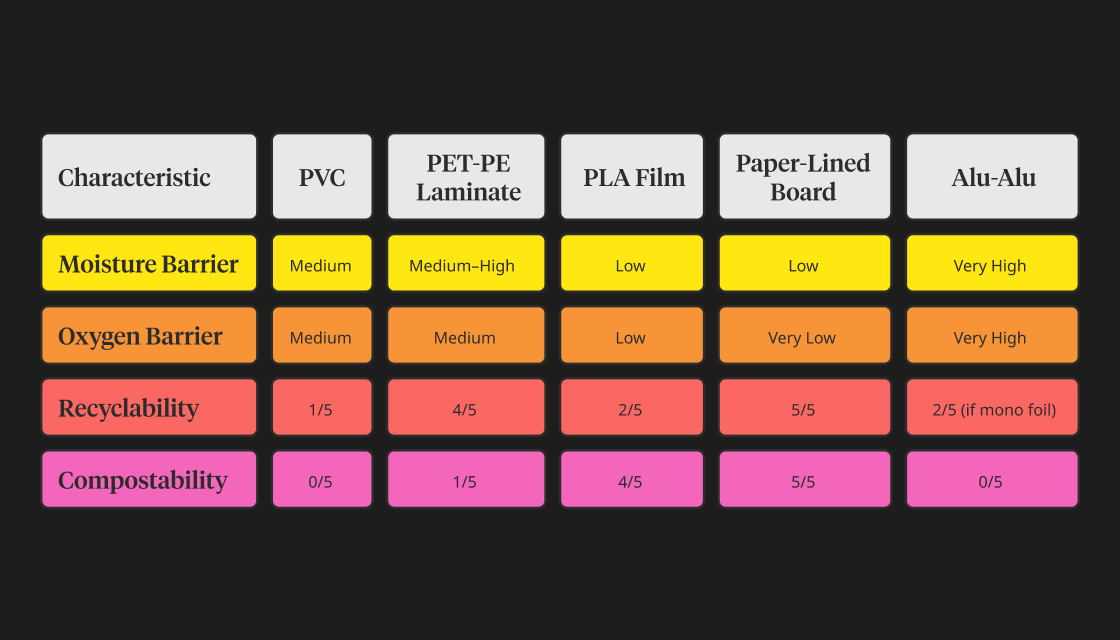

Material Barrier Score vs Environmental Rating

When evaluating different packaging options, it's essential to consider both the material barrier score vs environmental rating. This comparison helps in understanding how effectively materials can serve as moisture barriers in packaging while also assessing their overall sustainability.

The Circular Economy & Pharma

True sustainability goes beyond material choice. Leading companies explore closing loops within pharma packaging:

- Patient-facing take-back programs encourage resource recovery.

- QR codes educate consumers on recyclability.

- Blockchain traceability ensures supply chain transparency.

- Collaboration with retail chains creates drop-off points for used blisters aiding recycling efforts.

Circular design principles minimize material usage, enable easy disassembly, and promote resource recovery—a challenge but achievable through innovation. Stay ahead of evolving standards with our blister packaging compliance guide.

PULPAC develops plastic-free blister packs, reducing environmental impact while maintaining product integrity.

Exploring traditional materials lists alongside new methods inspires the adoption of eco-friendly pharma packaging alternatives prioritizing biodegradable films.

What Does the Future Hold?

Smart pharma packaging will be both intelligent and sustainable:

- QR-coded blisters provide recycling instructions enhancing user awareness.

- NFC-enabled smart packs monitor adherence & environment improving decentralized healthcare experiences.

- Modular formats combining PLA, PET & fiber create recyclable structures reducing carbon footprints.

- Customized regional solutions use PET for EU, PLA for India & paper-based options for nutraceuticals.

These innovations reduce carbon footprints while supporting patient experiences through accessible medications. Understanding differences between PVC vs PVC/PVdC aids selection aligned with sustainability goals. Explore future-ready innovations in smart blister packaging that improve patient compliance and traceability.

Innovations like Huhtamaki Push Tab® Blister Lid redefine eco-conscious designs offering plastic-free options meeting consumer demands.

Blister Pack Collective initiatives focus on responsible production addressing plastic pollution concerns globally.

Companies like Sonoco embrace energy-efficient manufacturing alongside paper-based & mono-material blisters supporting circular economy principles across supply chains.

Key Takeaways for Pharma Professionals

- The phase-out of PVC accelerates due to its environmental impacts & tightening regulations.

- PET mono-materials provide excellent recyclability & barrier function essential in pharma packaging.

- Paper-based & PLA materials suit nutraceuticals & low-sensitivity APIs, aligning with sustainability goals.

- Sustainable compliance enhances branding & supply chain efficiency; films like Klöckner Pentaplast kpNext™ R1 Base Film support this transition.

- Reducing plastic waste without compromising product integrity is critical; biodegradable & compostable options help achieve this.

- Solutions such as SÜDPACK PharmaGuard & EnviroSense® PaperBlister™ reduce waste while maintaining quality & safety standards.

Discover how child-resistant blister packaging ensures safety without compromising sustainability.

Conclusion

Anjali’s journey began with a troubling report but led to transformation. Her company evolved from an operational excellence focus to leadership in sustainable pharma packaging by embracing environmental stewardship.

Globally, pharmaceutical companies reimagine their role—not just protecting patient health but also stewarding environmental well-being through planet-friendly biodegradable & recycled packaging solutions.

Future breakthroughs won’t just protect medicines—they’ll protect the planet too. See how blister packaging for clinical trials is shaping sustainable, trial-ready solutions. Innovations like SÜDPACK PharmaGuard PP Mono-Material Blister Pack set new eco-friendly standards using PFAS-free & alternative materials, supporting sustainability efforts industry-wide.

As pharmaceutical roles expand merging health with ecological responsibility, every pack will reflect a commitment not only to quality but also planetary care through sustainable pharma packaging choices. Don't miss our editor's pick—complete guide to blister packaging—offering rich insights and best practices for pharma professionals.